BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

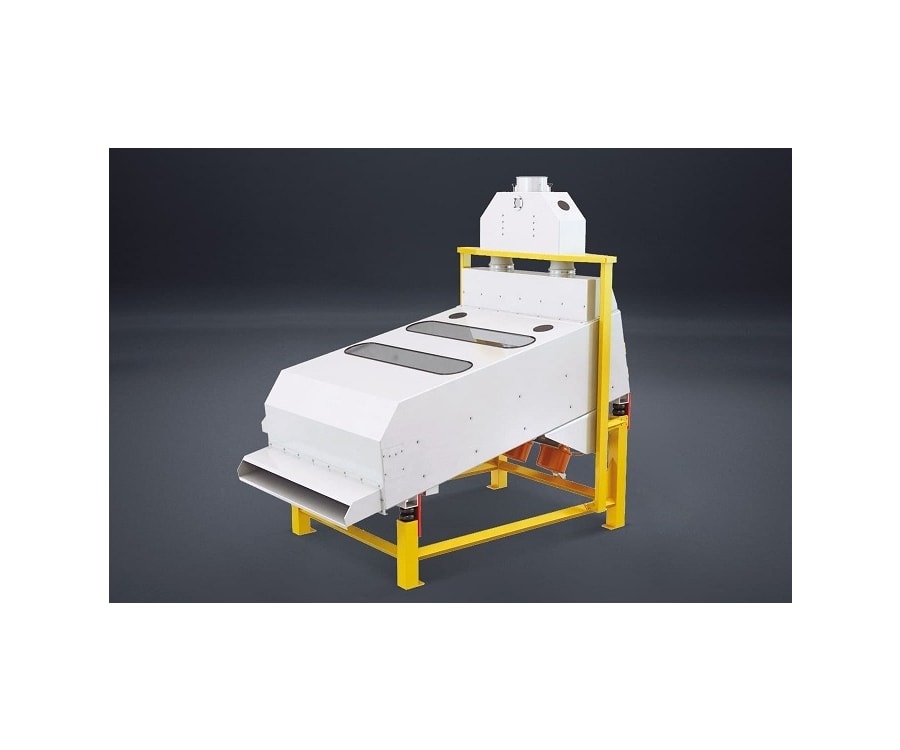

Grain Seperator | TCSI

Grain Seperator | TCSI

| GENERAL TECHNICAL DATA | |

| Capacity | Upon request |

| Adjustable inclination (angle) of screen | grades range 2 - 12. Due to such feature it can be used for any kind of cereals at maximum efficiency. |

Machine designed for the removal of fine and coarse impurities from cereal caryopses by sifting action. Due to its adjustable speed and inclinable screen, it can be used as a multilateral grain-cleaning machine.

- Trouble free operation by using vibro-motors

- Quick and easy replacement of screens and practical cleaning possibility

- Noiseless working condition

Structure

Vibrating structure supported by elastic shock-absorbing elements, containing the sifting body with two rows of sieves pairs Self adjusting grain feed Self cleaning of the sieve covers by means of rubber balls Transparent plexiglass panels for checking the cereal strata Steel or wooden made sieve frames equipped with easily replaceable perforated plates The vibrator motors, which provides the oscillation for the separator.

Working Principle

Vibrating process is maintained by means of vibro-motors, which are placed in the center of gravity of the machine. The grain feeding chamber and body which are mounted on the rubber shock absorbers by vibrating together and driven by vibro-mo tors convey the product into mid-section of inlet. The grain is separated uniformly on the entire surface of the screen by means of an adjustable regulating gate. If it is necessary, for better product flow another adjustable regulating gate can be fixed to the inlet of the screen. When the grain passes through from the first screen to the second one, larger size impurities or foreign particles are kept by the first screen and directed to coarse offal discharge line. The remained smaller size impurities or foreign particles, which pass through the second screen, are transferred to fine offal discharge line. Then, the cleaned product is transported to an air canal or tarar.

Features & Advantages

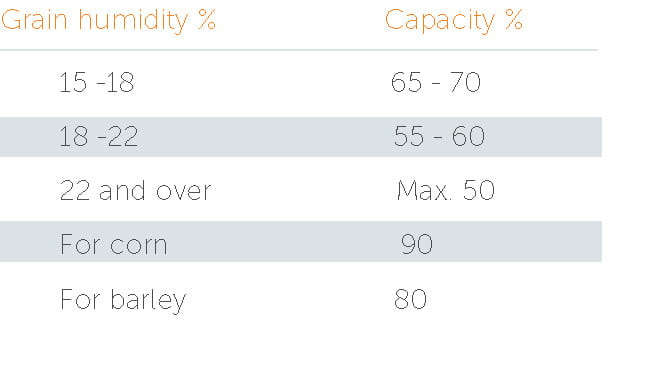

Note: All figures given on table are max.

Values to be considered for wheat and rye, which contain 15% humidity. For higher humidity containing grains below mentioned values should be considered.

| Options | Description |

| Application fields | At food processing industries Flour and semolina mills Seed cleaning plants Cereals cleaning and calibration centers Malt factories Feed mills Cereal storage silos At other similar industrial plants |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production