RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

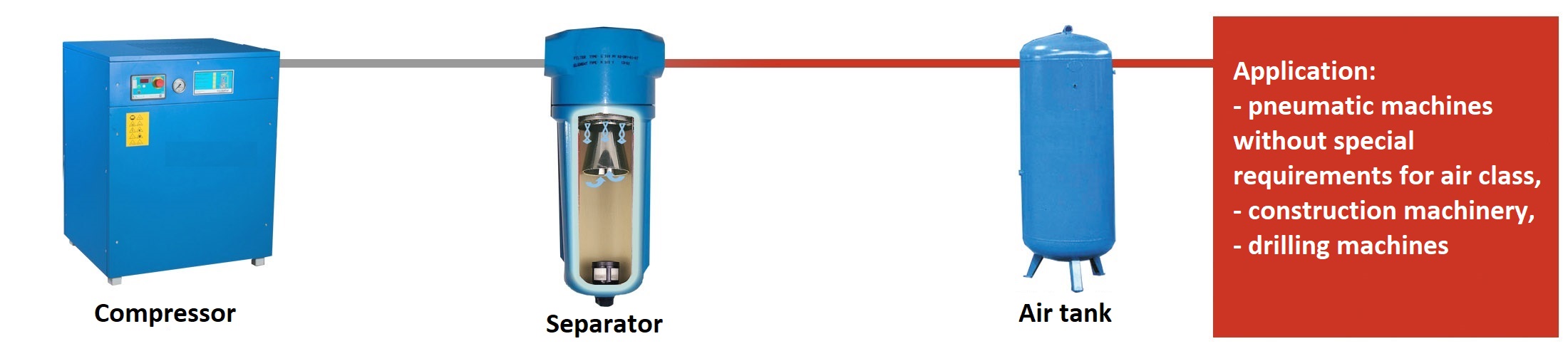

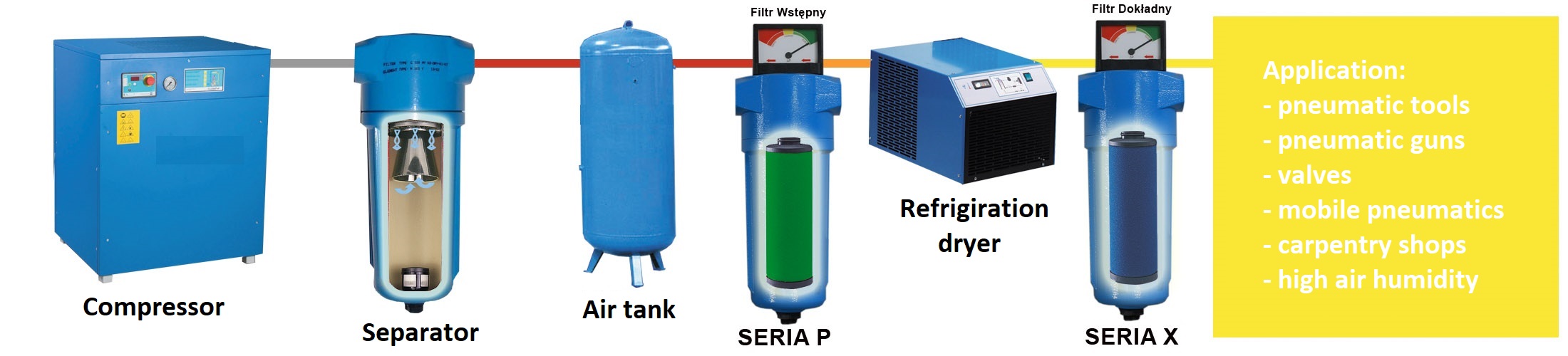

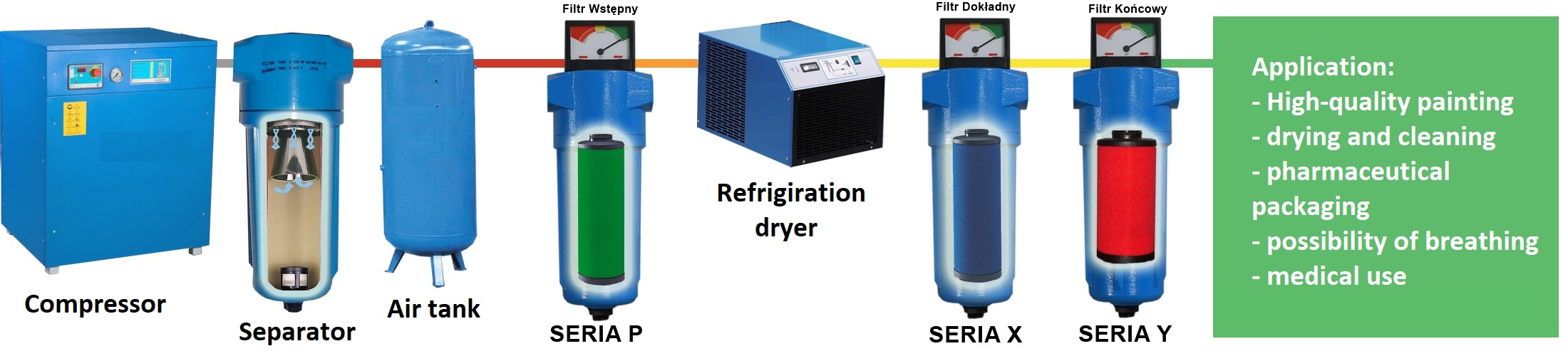

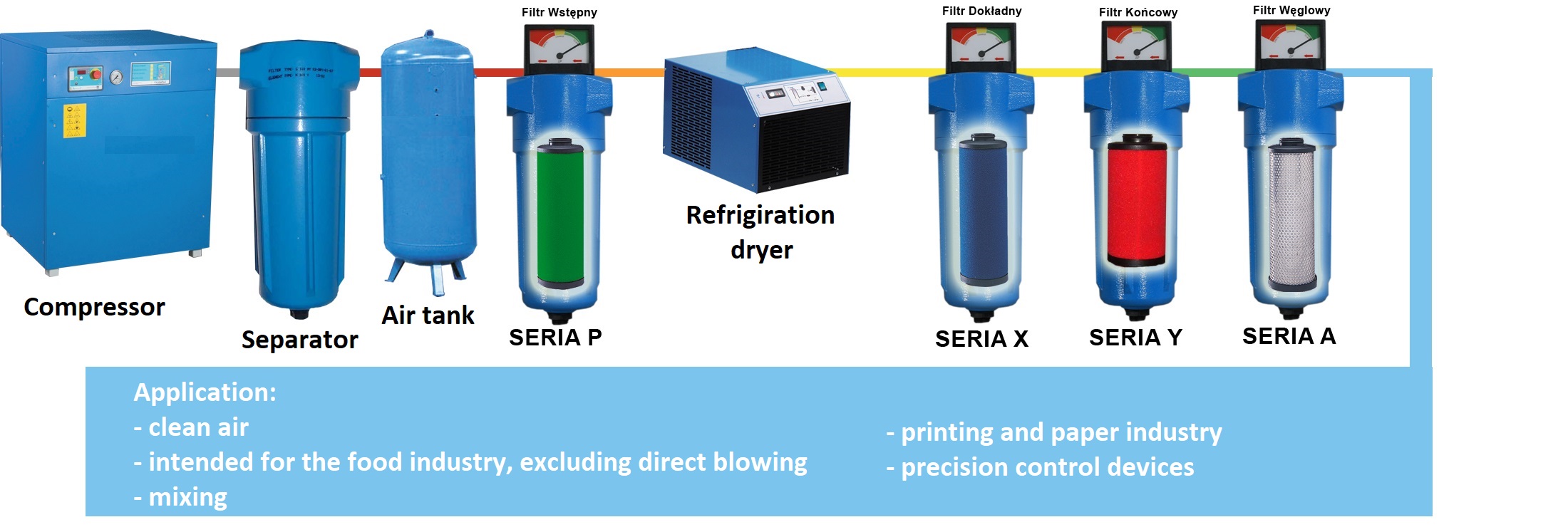

Air compressors

equipment

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production