RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

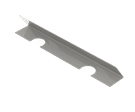

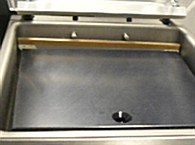

Vacuum packaging machine Boxer 42 HENKELMAN

Vacuum packaging machine Boxer 42 HENKELMAN

| GENERAL TECHNICAL DATA | |

| Chamber dimensions (L x W x H): | 370 x 420 x 180 mm |

| Machine dimensions (L x W x H): | 528 x 493 x 440 mm |

| Seal bar (L): | 420 mm |

| Pump capacity: | 21 m³/h |

| Machine cycle: | 15-35 sec |

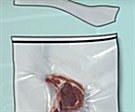

Basic vacuum packaging machine for the food packaging of products with all shapes and dimensions. Available as a basic table-top model and as a full option vacuum packaging machine.

- Standard with 10 program memory

- Standard Time control

- Free options: Cut-off and Wide seal

- Standard Double seal

- Standard Soft Air

- Full option

| Options | Description |

|

Label printer Zebra ZD410 |

|

Inclined insert plates |

|

Polyethylene inserts in the vacuum chamber are standard on each machines and serve to optimize the duration of the work cycle and adjust the position of the package inside the chamber. For two-chamber models, possible to produce special inserts for the cover to save time and reduce gas consumption by reducing the volume of the vacuum chamber. |

|

Cutting wire string |

| Gas injection | Between vacuum and sealing cycles, possible to inject gas to extend shelf life, protect of sensitive products, and prevent the loss of natural color of the product |

| Boiling sensor | Equipped with a boiling point detector because low pressure in the chamber and liquid products quickly reach their boiling point |

| Universal trolley | The universal trolley is suitable for tabletop models, increases the mobility of equipment and is intended for storing bags and labels |

| Service kit | Supplied with all models. This kit contains consumables (silicone and other seal, teflon tape, original oils) required for periodical maintenance |

|

Vacuuming hot products allows you to vacuum food with high temperatures (from 65 ° C and above) |

|

Separate sealing / trimming device designed for using vacuum machine with shrink diptanks and shrink tunnels |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production