RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

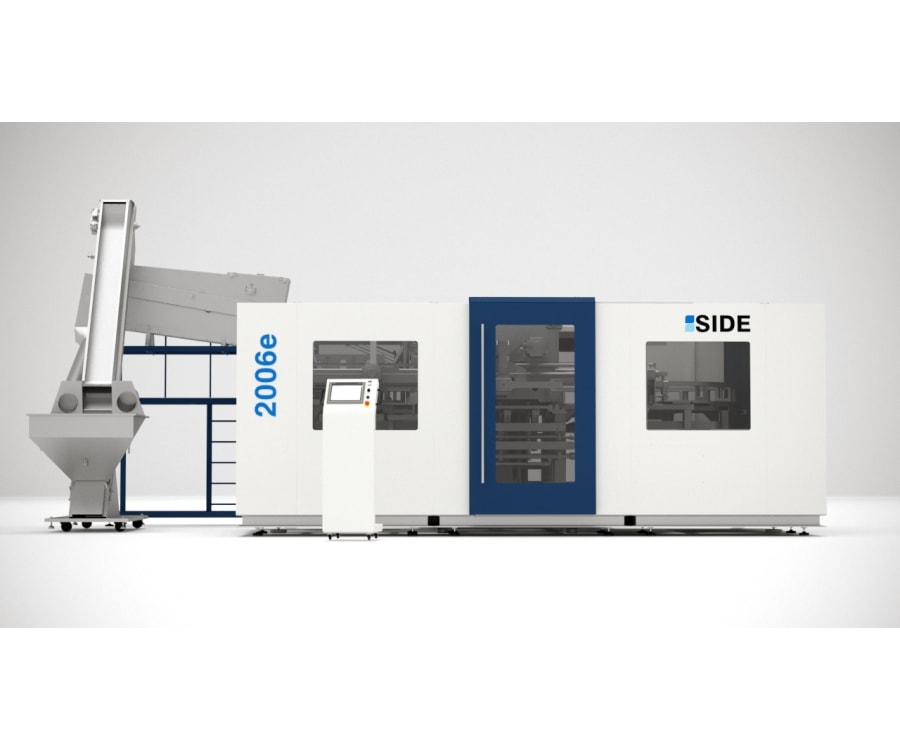

1 - Blow moulding machines 10000 bph 2006e SIDE

1 - Blow moulding machines 10000 bph 2006e SIDE

| GENERAL TECHNICAL DATA | |

| No. of cavities | 6 |

| Output | up to 10000 bph |

| Bottle size | 250-3000 ml |

| Diameter | max 120 mm and height max 371 mm |

| Preform size | Neck diameter min 18 mm, max 60 mm |

| Total installed capacity | 130 kW |

| High pressure air | Max. 40 bar. Quality min 1.4.1, ISO 8573-1:2001 Volume flow rate 300-500 m³/h |

| Low pressure air | Min 6 bar. Max 10 bar Quality 3.4.3, ISO 8573-1:2001 Volume flow rate de 90 m³/h |

| Water | between 6-10ºC temperature with 3-5 bar of pressure. |

Maximum efficiency and reliability for large-scale production.

These models are designed for production that demands maximum efficiency and reliability. Capable of producing up to 10000 containers per hour, they have the latest technological advances built in, with the aim of guaranteeing operational simplicity and high reliability in large-scale packaging manufacture processes.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production