RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

Semiautomatic retort cager

Semiautomatic retort cager

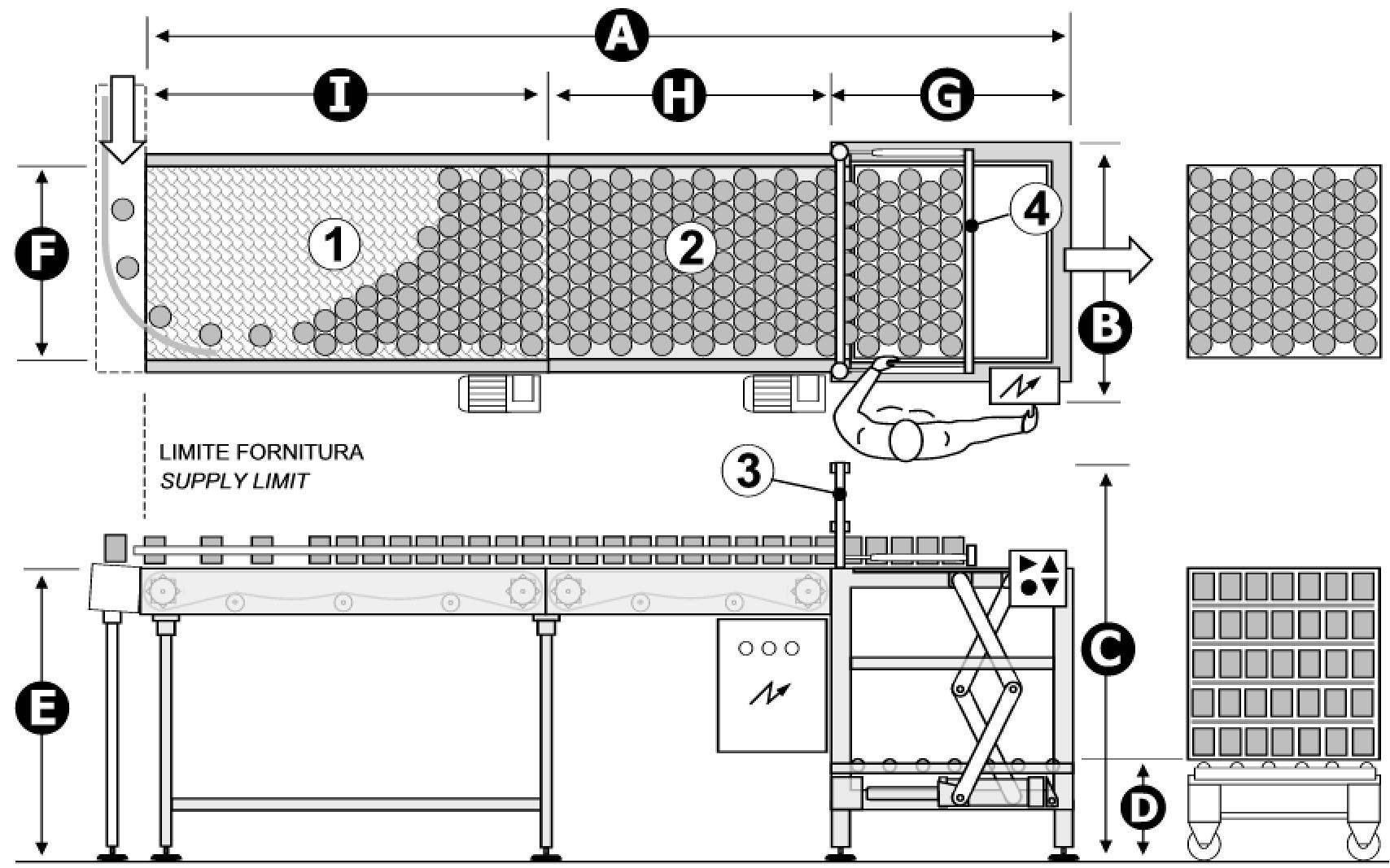

| GENERAL TECHNICAL DATA | |

| Installed power | 3 kW |

| Weight | 1500 kg |

| Diameter of cans min-max | 50-150 mm |

| Height of cans min-max | 40-250 mm |

| Cage length | 950 mm |

| Cage width min-max | 820-920 mm |

| Cage height min-max | 780-920 mm |

Semiautomatic crater designed to balance speed and cost. Suitable for most small and medium production lines with round containers such as cans and jars. The worker is assisted by various devices to decrease filling time and reduce fatigue caused by repetitive movements.

|

A |

B |

C |

D |

e |

F |

G |

H |

I |

|

4660 |

1240 |

2105 |

507-532 |

1480 |

820-920 |

1160 |

1500 |

2000 |

Note: The data indicated in the table are subject to change.

Technical description

- For containers suitable for push-loading - symmetrical, flat sides, no protruding edges, and medium width-height ratio (tall+thin cans are unstable; flat+wide cans overlap)

- Up to 2 layers per minute with 1 trained worker

- For rectangular Layer-in-Divider crates with false bottom

- Receiving belt in stainless steel (for glass) or plastic (for metal cans); rubber pushing belt for best traction

- Adjustable side rails for different can diameters

- Adjustable gear reducer to vary belt speed

- Photo-eye to stop the lifter at the precise height

- Accepts standard-size Panini crates for diameter 12001400 static retorts and diameter 1200-1800 rotary retorts

- Built in stainless steel AISI 304

Operation

- (1) The Receiving Belt (1) receives cans from the line. Made of non-gripping material so round containers align themselves naturally in a staggered formation.

- (2) The worker places a divider by hand and actuates the lifter to bring the layer to the level of the belt.

- (3) When cans are enough to form a layer, the worker activates the Pushing Belt (2), that pushes the layer forward onto into the crate.

- (4) The Leading Bar (4) leads the cans as they move forward to keep the layer compact.

- (5) The Blocker (3) presses down on the last row of cans remaining on the belt, so they don't fall off when the lifter is lowered.

- (6) The worker repeats the procedure until the crate is completely full, manually removes the full crate, inserts an empty crate and repeats.

.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production