RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

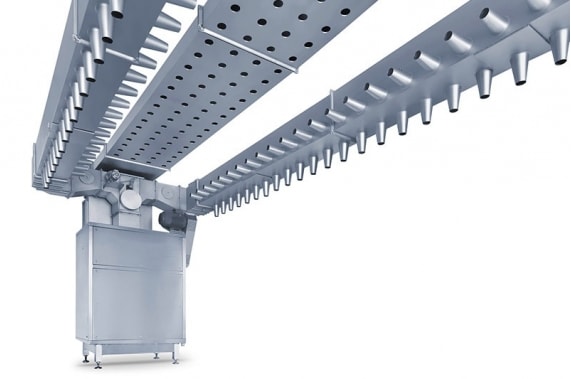

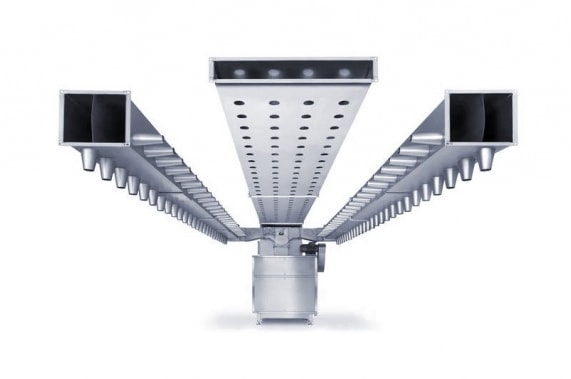

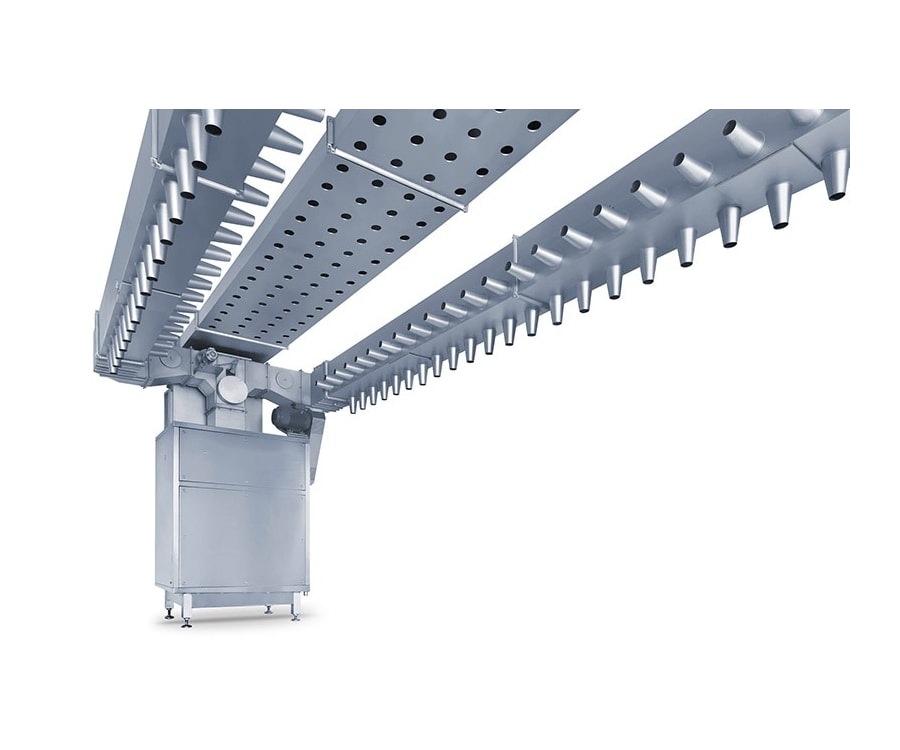

Conditioning and ripening rooms

Conditioning and ripening rooms

| GENERAL TECHNICAL DATA | |

| Capacity | up to 100 trolleys |

| Temperature range | +2 +40 C |

| Relative humidity | From 80% to 95% |

| Heating energy | Warm water |

| Electricity | |

| HP or LP steam | |

| Coolant agent | Freon / Frigen |

| Ammoniak | |

| Cold brine, glycol. R 64 | |

For ripening/fermenting, drying, smoking and conditioning of raw sausage products, hams, meat, fish or cheese

- circulation mixing unit can be placed in. behind or on top of the processing room

- steam generation through the humidity of the product itself and also through electrical steam generation, low pressure steam or water injection via nozzles

- step less speed control of the fan: air speed from 0.5 m/s - 15.0 m/s

- step less control oft the changing flap motor

- fully automatic outside air conditioning

- cleaning through high pressure pump

| Options | Description |

| Recirculation of hot air | use of heat coming out of the cooling machine through installation of a additional heat exchanger |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production