RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

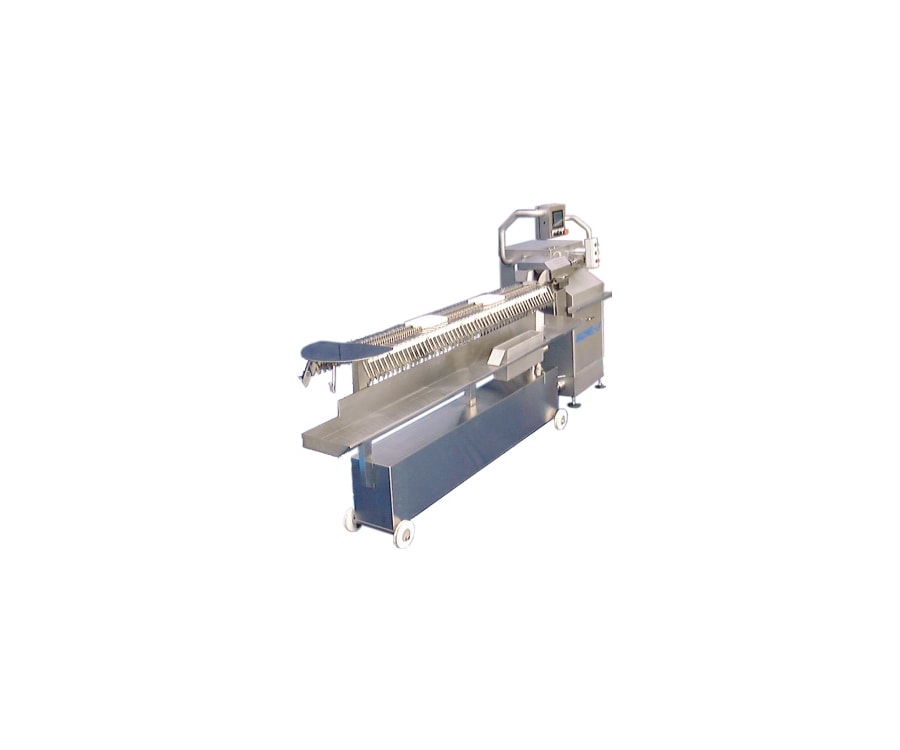

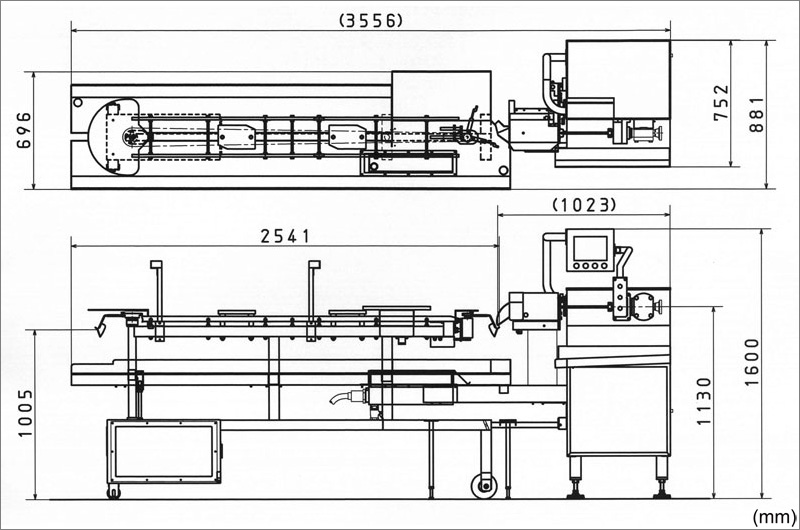

SAUSAGE HIGH SPEED LINKING AND HANGING SYSTEM MACHWEL (NATURAL CASING)

SAUSAGE HIGH SPEED LINKING AND HANGING SYSTEM MACHWEL (NATURAL CASING)

| GENERAL TECHNICAL DATA | |

| Natural casing | Max. 800 pcs/min |

| Casing szie Natural Length Natural |

12-25 mm |

| Power | 4,2kW |

| Dimensions | H1610x820x3600 |

| Weight | 500 kg |

Production of up to 800 links of constant size and weight natural casing sausage per minute. In the conventional production of natural casing sausage, it was considered impossible to make natural casing sausage with constant weight and length. However, when Hitec introduced "LINKWEL" in 1998, this belief was no longer true for natural casing. Now in 2001, Hitec is proud to introduce the "MACHWEL". The world's first fresh sausage stuffing and link separating machine sure to revolutionize the fresh natural casing sausage industry

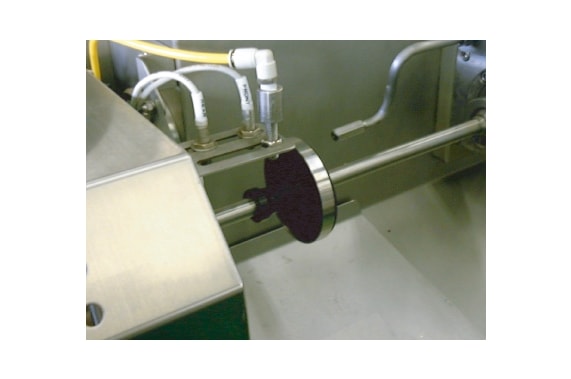

- Casing Advancing mechanism and Tail End Detector The "MACHWEL" reduces casing breakage using a patented stuffing design that is unique to the conventional styles used.

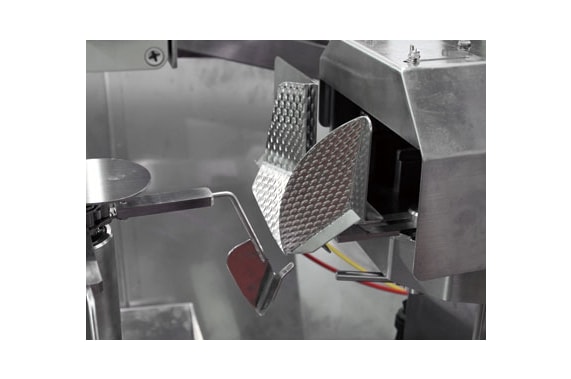

- Stationary chute A revolutionary breakthrough over the conventional looper horn which moves to hang product over hooks. Our system allows precise hanging by simply allowing the product to "slide" to the conveyor hooks without the need for more wear parts as on a looper system.

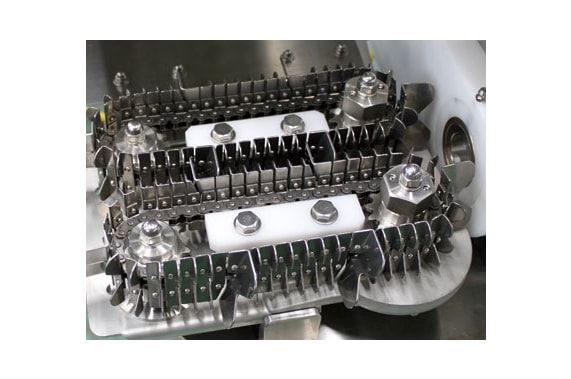

- Various Linking Chain Available in various lengths from 3 pitches (1.125 inches) and longer. "MACHWEL" is available to run half pitch sizes.

- Water Device With installing an optional water device, the process of tying the casings in the front and the tail has been eliminated. This device helps to increase both productivity and casing utilization.

| Options | Description |

| Collagen casing | Manual insertion |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production