RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

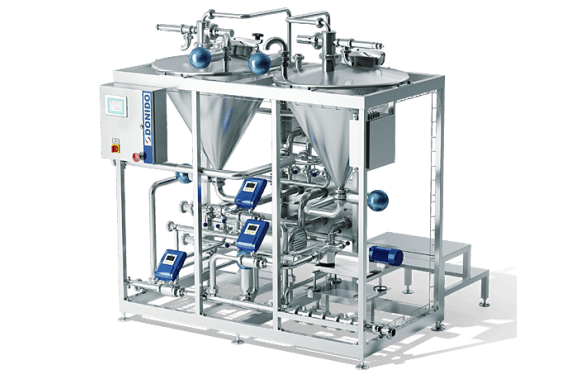

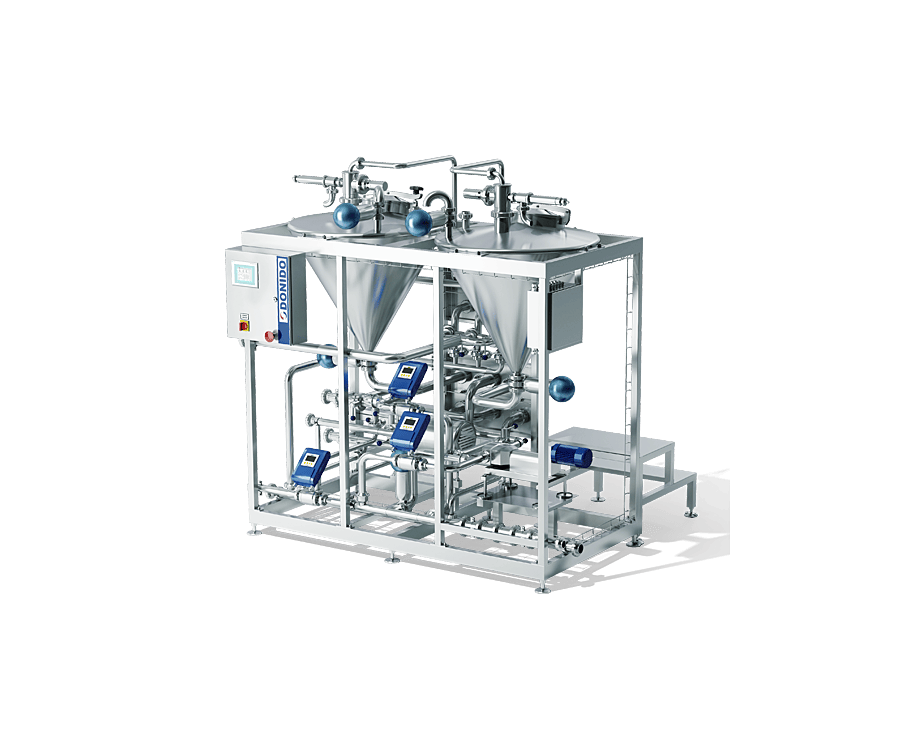

Module for liquid and viscose additives | DONI®Liquid Plus

Module for liquid and viscose additives | DONI®Liquid Plus

| GENERAL TECHNICAL DATA | |

| Productivity ranges: | DONI®Liquid Plus 0.5 from 50 to 500 l/h with a power supply 0,55 kW; DONI®Liquid Plus 1.0 from 500 to 1 000 l/h with a power supply 0,75 kW. DONI®Liquid Plus 2.0 from 1 000 to 2 000 l/h with a power supply 1,5 kW; DONI®Liquid Plus 3.0 from 2 000 to 3 000 l/h with a power supply 2,2 kW. |

| The volume of the above hoppers: | 200 l, but can differ depending on the specifications of the production process |

The module is designed for automated dosing of liquid and viscose additives (such as jam, vegetable fat etc.) which can be done before or after the heat processing of the product. When the additives are sterile they can be fed in doses or in line, just before packaging. DONI®Liquid Plus is integrated in the production lines of drinking fruit milk and yogurt. The module contains two cone hoppers which allow the continuous cycle of operation with two different additives. When operated with sterile jam the hoppers should be aseptic. A system of valves, flow meter and micro-processing control ensures precise dosing in line or in defined volumes. The Module requires CIP washing. It is suitable for medium and large sized dairy factories.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production