RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

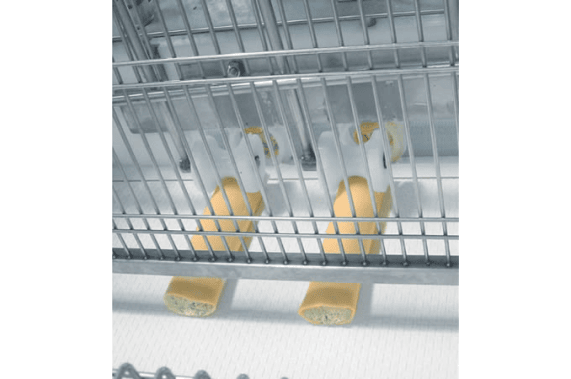

Production line for pre-cooked cannelloni ITALPAST

Shaping unit for filled cannelloni obtained from pre-cooked sheet pasta

High performances by output of over 15000 pcs per hour

The sheet pasta for production of pre-cooked cannelloni, obtained from automatic, continuous sheeter, is placed onto the calibrator feeding the cooker, which can process sheet pasta featuring 500 mm, in width and changeable thickness depending on our customer's requests. After cooking the sheet pasta is fed into a cooking/washing basin to remove surface starch, then it is transferred to a conveyor belt equipped with proper devices to shape and cut the filled cannelloni.

The equipment for shaping of pre-cooked cannelloni obtained from sheet pasta is composed of the following:

- conveyor belt for pre-cooked pasta usable width 600 mms., made in stainless steel with belt in polyurethane, equipped with electronic speed variator;

- knife group for longitudinal cut of sheet pasta;

- filling doser from 3 up to 8 parallel cannelloni depending on size and width of the pre-cooked sheet pasta. Fully dismountable and washable, suitable for coupling with the dosing pump;

- shaping/roll up device of cannelloni;

- pneumatic device for guillotine-cutting of filled cannelloni;

- conveyor belt for cannelloni, usable width 600 mms., length 2000 mms. approx.;

- electric control panel featuring PLC system and touch-screen, made in stainless steel casing IP65, comprising control devices for conveyor belts speed and regulation of cutting length of cannelloni by timer or encoder (at choice);

- machine running electro-pneumatically, fully in stainless steel, enabling full washing and sanitization.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production