RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

Showering and intensive cooling houses

Showering and intensive cooling houses

| GENERAL TECHNICAL DATA | |

| Capacity depends of the caliber of the product | 1000-2400 kg |

| Installed power | 20 kW |

| Dimensions w x d x h | 1680 x 6650 x 2800 мм |

| Refrigeration power | 108 kW |

| Dimensions pf the trolley | 1010 х 1030 х 2020 mm |

Showering and intensive cooling houses

The Showering and Intensive Coolinghouses stand for modern and efficient production processes and minimum product cycle times. Immediately after the thermal treatment of meat, sausages and other kinds of food the product can be cooled down to a requested core temperature and packed. The air is cooled down in the circulation process. This process is monitored and controlled by a microprocessor.

- microprocessor-controlled cooling conditions

- ready to plug in delivery ex works - fast installation the spot

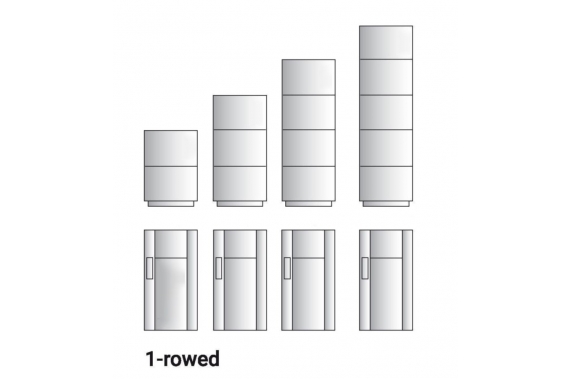

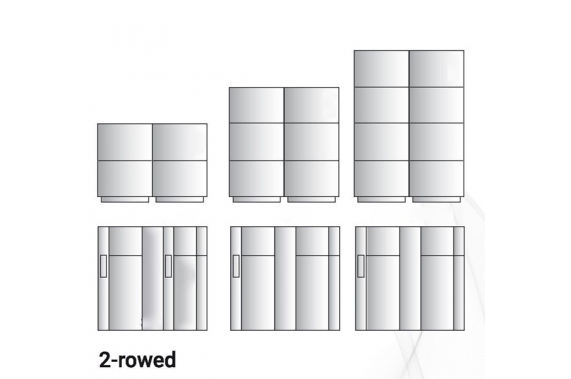

- 1 -truck to 6-truck units

- microprocessor control K-Touch 4012 available in many languages

- cooling down to 6 °C core temperature possible

- stainless steel evaporator

- all current coolants usable

Your benefits:

- minimum loss of temperature and minimum loss of weight

- short cycle times by immediately ready to pack products

- saving of cooling surfaces and storage space

- shelf life of product extended because of faster and monitored cooling down

- increased slicability strength with cold cuts

- attractive look of the product

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production