BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

HIT screw compressor 2.2-7.5 kW

HIT screw compressor 2.2-7.5 kW

| GENERAL TECHNICAL DATA | |

| Power: | 2.2-7.5 kW |

| Yield: | 320-900 l/min (19,2-54 m3/h) |

| Working pressure: | 8-13 bar |

| Dimensions mm | 730 (700) х 650 (580) х 630 (780) |

| Weight kg | 88-112 |

The screw compressor of the HIT-3G series is a comprehensive solution in the form of a compressed air source in the company, constructed on the basis of the latest world technologies associated with the highest quality materials. The HIT compressor is equipped with a microprocessor panel of the control system, which is a novelty in this class of compressors. This solution allows for easy and legible operation of the device. The system automatically detects irregularities in operation and informs by displaying the type of failure, and if there is a risk of damage to the compressor, it will turn it off

HIT screw compressor - Description of components

L9 control panel

The HIT compressor is equipped with a microprocessor panel of the control system. It informs the user about the compressor's operating mode. The clear and detailed display provides information about:

- the device's defect through a detailed alarm code

- operating temperature of the screw module

- total number of hours worked and under load

- time remaining until the service inspection.

- fault memory function.

- Pressure under your control - By installing a pressure transducer, you can change the minimum and maximum pressure via the control panel. The working pressure is shown on the display in tenths of bar.

Automation

Modern automation, based on the highest quality components , protects the compressor against:

- voltage drop in the electric network

- failure of the power phase

- incorrect direction of engine rotation

- overload of the engine

- too high oil temperature

- too low oil temperature

- starting of an unloaded screw module

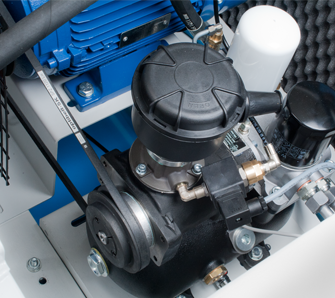

Screw module

Made of the best components, the pump system of the HIT series compressor has one of the best efficiency ratios on the market in proportion to the engine power. Reliable drive transmission by means of a belt transmission, which ensures stable operation of the compressor. A refined oil-air filtration system allows to obtain a low oil content in the compressed air at the outlet of the compressor (<4ppm). Throughout the service interval, the compressor maintains its efficiency at the highest level.

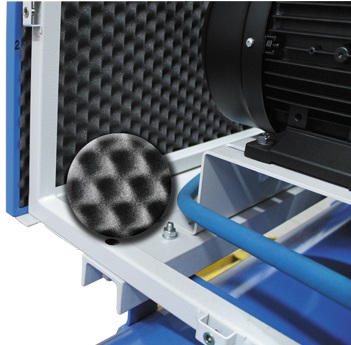

Soundproof housing

The housing of the HIT screw compressor has a compact housing , which has been made with high precision. The sound insulation boards installed inside the casing together with the compressor's constructional arrangement made it possible to achieve the noise barrier of 67 [dBA], which is one of the best results in this class of compressors.

| Options | Description |

PLC L26S  |

Control panel has an alphanumeric LCD display - messages about the compressor's operation are transmitted in 9 languages (Russian, Polish, English, German, French, Italian, Spanish, Turkish, Portuguese) - the integrated clock allows you to set 3 work schedules for one day a week. RS485 port allows you to connect the compressor to a computer in order to monitor the operation of the device. Possibility of connecting a GSM module - receiving messages in the form of text messages about the compressor's operation. Automatic compressor start-up after power failure in the electrical network. Possibility of connecting the compressor with the L26S in a cascade |

| Automatic preinstalled drain HD-MD600 | Min. / Max. temperature (° C) +1 / +50 Operating pressure 0-16 bar. Condensate Dirty with oil and no oil Aluminum body lined with a hard, abrasion-resistant coating The indispensable system in modern condensate management. The automatic electromagnetically controlled check valve, based on continuous measurements of the condensate level in the tank, opens as needed and causes a continuous discharge of condensate from the compressed air system without pressure loss. |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production