RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

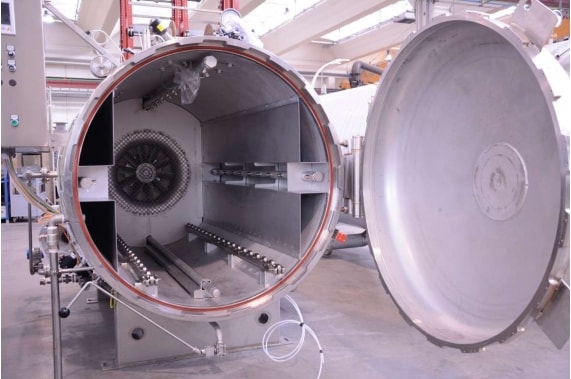

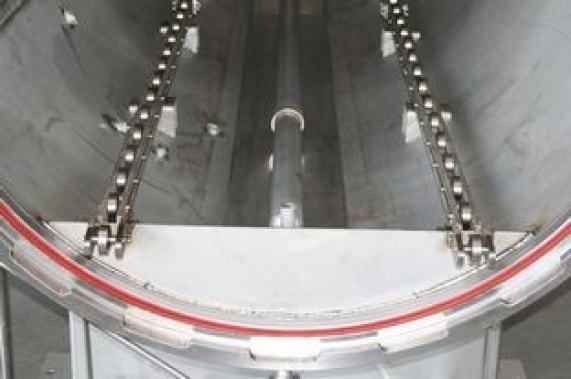

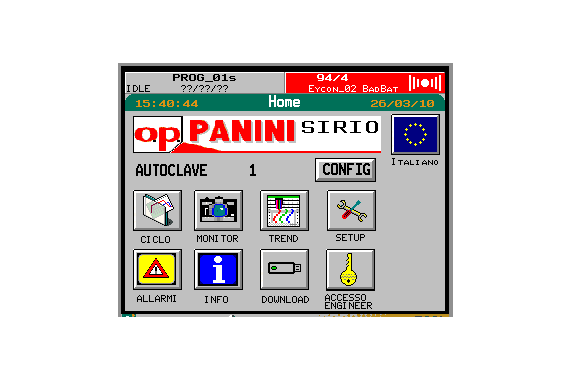

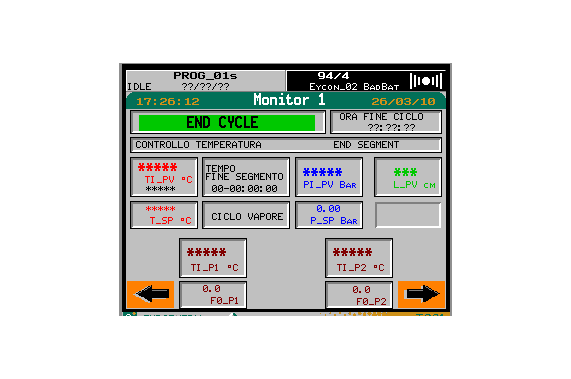

Retorts for cans UNIVERSAL-A OP Panini

Retorts for cans UNIVERSAL-A OP Panini

| GENERAL TECHNICAL DATA | |

| Trolley quantity | 1-7 pcs |

| Type of the product | Cans |

| Diameters of retort | 1200 - 2000 mm |

| Lengths of retort | 2000 - 8000 mm |

| Steam pressure max | 4 bar (with 150°C) |

| Doors type | Horizontal |

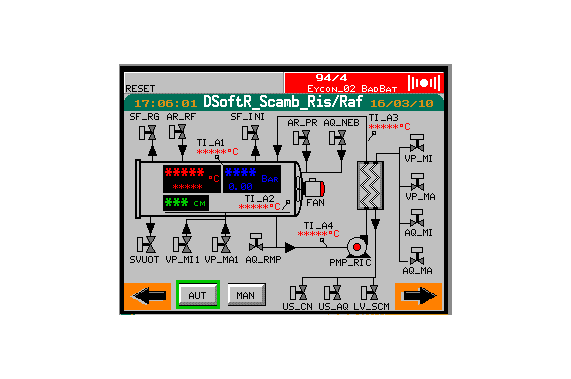

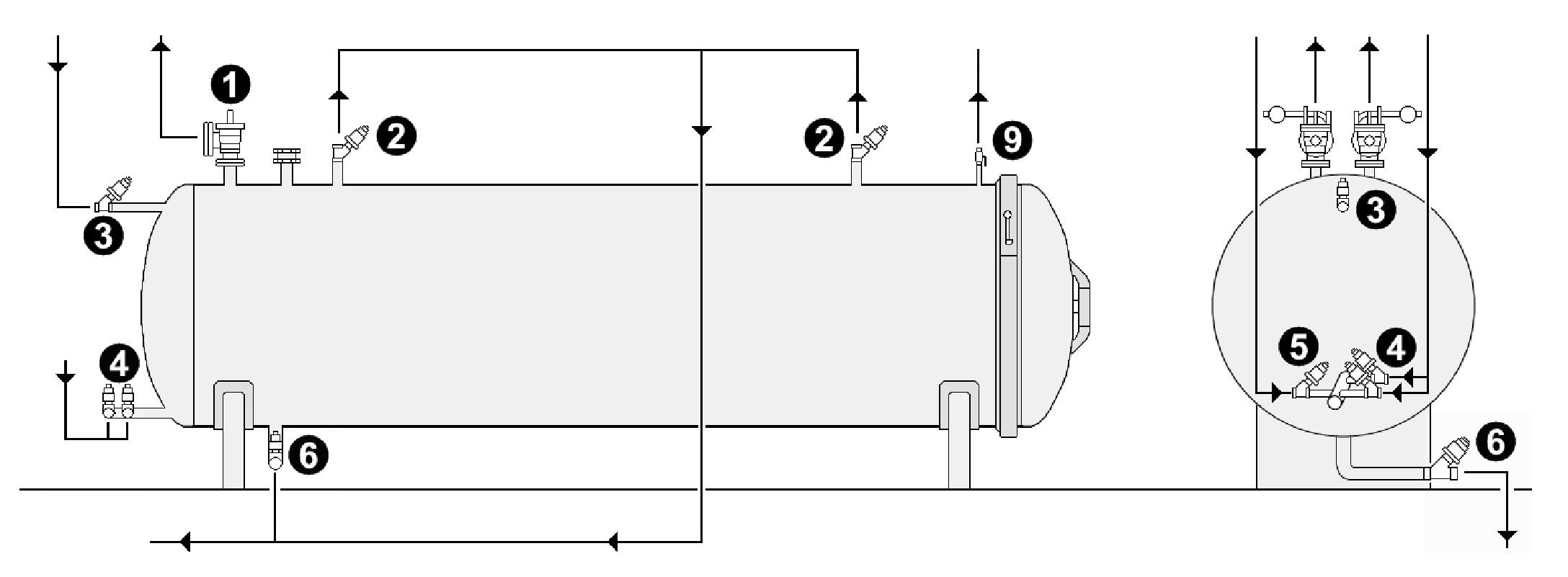

Sterilization retort for canned food products, designed for minimal capital outlay. The retort processes tin cans in saturated steam (no air overpressure during holding). Flood cooling with bottom-inflow/top-outflow (with air overpressure) guarantees good cooling without needing a circulation pump. The retort has the basic kit of control valves plus a bleeder vent to guarantee maximum temperature uniformity, in accordance with US FDA retort regulations.

Technical description

- Direct steam heating

- Bleeder vent guarantees temperature uniformity during sterilization

- Flood cooling

- Compressed air overpressure during cooling only

- Insulated pressure shell with sheet aluminum cladding

Valve kit:

The Universal-A model is designed for a basic set of valves needed to control a saturated steam sterilization process:

1. Safety

2. Vent x 2

3. Air

4. Steam x 2

5. Water

6. Drain

7.-

8.-

9. Bleeder vent

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production