RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

Vacuum sealing thick and aluminium bags Bi-active

Vacuum sealing thick and aluminium bags Bi-active

| GENERAL TECHNICAL DATA | |

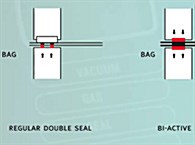

| Industrial packaging | Bi-active sealing technology is often used in non-food industries to work with delicate products such as semiconductors, mother boards, computer components and hard drives. Such packaging requires optimal protection of goods from moisture and dust |

| Food Packaging | Bi-active sealing is also used in the food industry (for example, when sealing metallized doy-pack bags with coffee) |

| Double-sided sealing | Bi-active sealing strips on both sides of the bag. One strap in the vacuum chamber, other fixed on the lid of the packer. Thus, the bag is sealed on both sides, which guarantees excellent sealing quality heated up to +170 ° C |

Bi-active sealing designed for vacuum packaging of food and non-food products

A vacuum packer with bi-active sealing working with aluminum bags or bags of extra thickness (more than 180 microns). These types of vacuum bags are the most difficult to package. As a result, the need for bi-active sealing is becoming an essential requirement.

Know-how of sealing technology

The development of sealing technology does not stop there. Contact us for advice. We will help you find the optimal configuration of the sealing types, the necessary sealing pressure, and also offer our recommendations to achieve optimal packaging quality depending on the product and your process.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production