BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

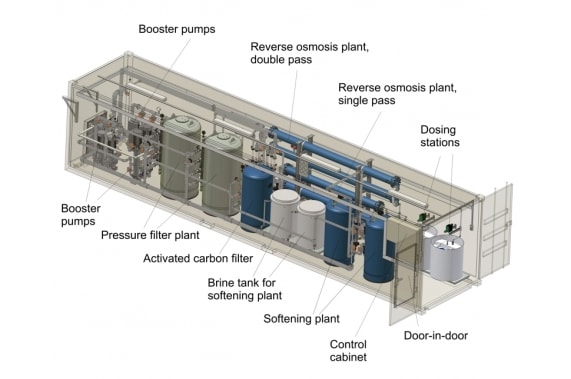

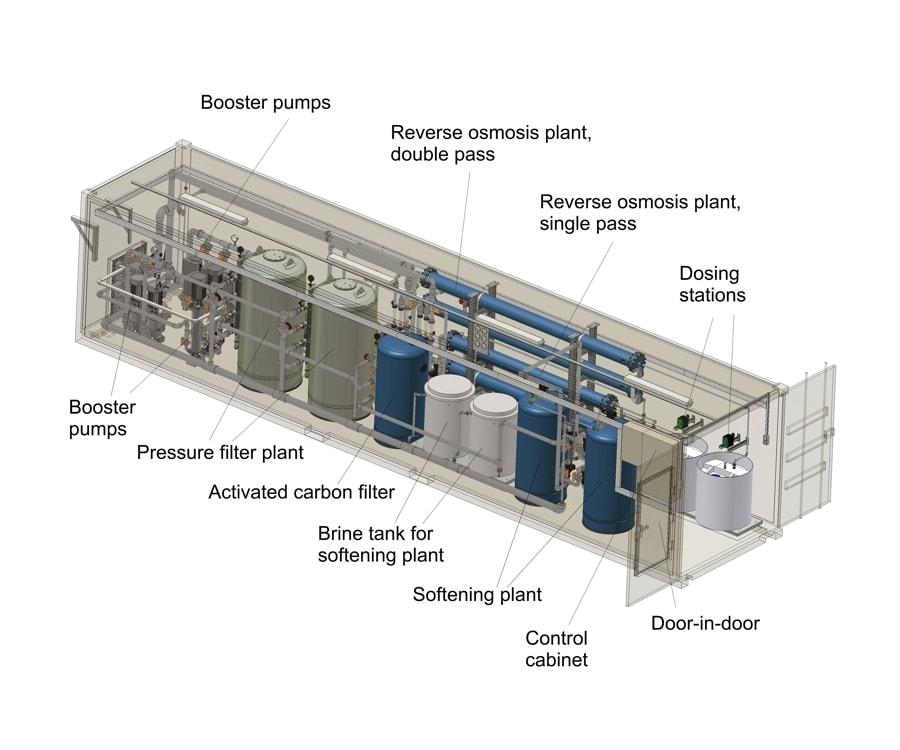

Complete water treatment plant in containers - ready for use EUROWATER

3D drawing of container

Above, you see an example of a fully equipped container. The container has been designed for a power plant and the water will be used for cooling water (8 m³/h), boiler water for high pressure steam turbine (6 m³/h), and drinking water. The container includes the following plants: Active carbon filter, pressure filter plant, softening plant with brine tanks, dosing stations, bag filters, doubble-pass reverse osmosis plant, dealkalization plant, booster pumps, and control cabinet. The shown container is insulated and equipped with door-in-door, light, and air-conditioning.

The concept

A water treatment solution consists of several treatment steps, e.g. filtration, softening, and demineralization - all controlled from a central control cabinet. These units must be put together on site. If the end-user or the contractor is uncertain if the installation can be carried out locally within the determined economic and temporal scopes, it can be an advantage to order a water treatment plant (container or frame-mounted) which is ready for use when supplied.

The solution is complete with all internal piping and wiring factory-built. The whole plant has been performance and pressure tested in our factory. This safety can be achieved with a EUROWATER frame-mounted plant or a container-installed plant.

With a container, you also have the advantage that the container itseslf is an actual building which in this way can be left out in the project. The containers can be delivered with and without insulation and can be equipped with lighting, air-conditioning, door-in-door, emergency shower, etc. We have constructed many different custom-made plants adapted to specific demands and wishes. Below, you can see different examples of this. We are happy to make quotations for start-up of plants and training of the operating crew.

- Complete water treatment plant in a 20 feet container. The solution consists of dosing, carbon filtration, softening, and demineralization through a reverse osmosis plant.

- 40 feet container with water treatment consisting of oxydation and filtration in a pressure filter plant type TFB 20. The plant has a capacity of 90 m³/h.

- 64 m³/h demineralized water produced in a reverse osmosis plant. A dosing plant is also installed in the container.

-

EDI plant with a capacity of 60 m³/h totally demineralized water with a very low conductivity and silica acid content for producing boiler water for high pressure steam turbine. The pipe system for the treated water is made in PP (Polypropylene) connected by welding and each takes app. 15-20 minutes to make. In total, 570 weldings have been made for this plant. Each EDI cell is fitted with own test cock.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production