BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

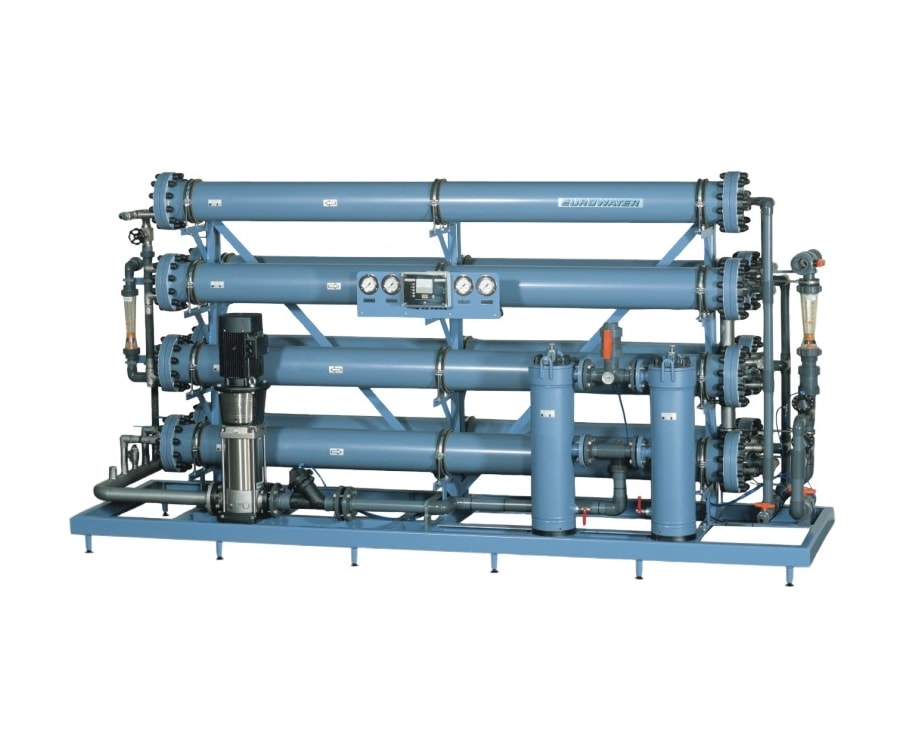

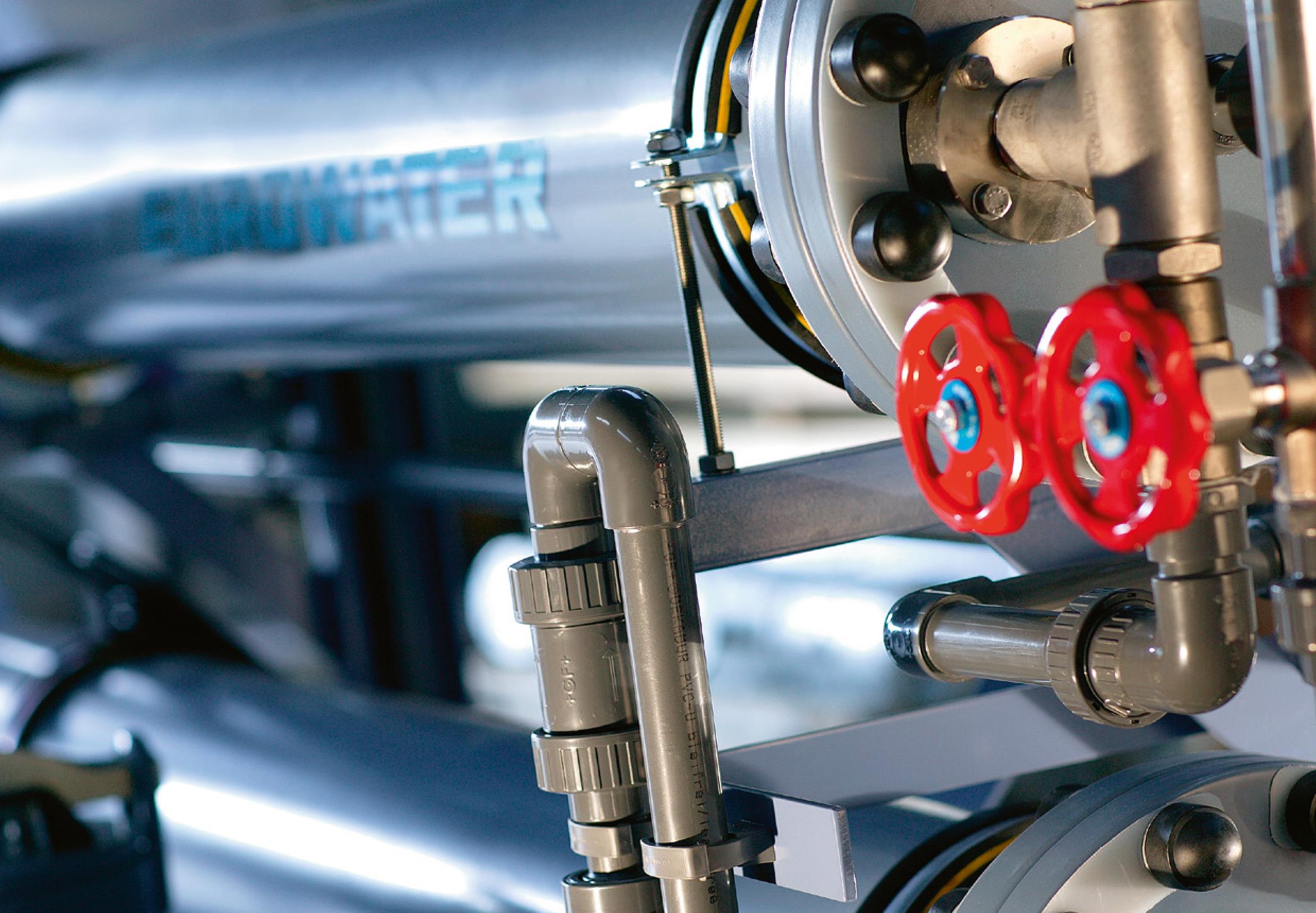

Reverse osmosis units (RO units) EUROWATER

Reverse osmosis units (RO units) EUROWATER

| GENERAL TECHNICAL DATA | |

| RO A1 Flow rate: Up to 180 l/h. | Wall type and floor type model. Centrifugal pump, prefilter of 1 µ, control panel with conductivity meter and automatic quality control, as well as flowmeters of PVC |

| RO B1 Flow rate: Up to 2,4 m³/h. | Vertical pressure pipes of stainless steel. 4" membranes. Adjustable circulation, centrifugal pump of stainless steel, prefilter of 1 µ, control panel with conductivity meter and automatic quality control, flowmeters in PVC, and quality rinse valve. |

| CU:RO - compact units with RO Flow rate: Up to 2 m³/h | Complete RO B1 system with pretreatment (carbon filtration and/or softening). Easy, quick, and safe installation thanks to mounting on frame with all internal piping and wiring already made. |

| RO B2 Flow rate: Up to 9,6 m³/h. | Horizontal pressure pipes of stainless steel. 4" membranes. Centrifugal pumps in stainless steel, prefilter of 1 µ, control panel with conductivity meter and automatic quality control, flowmeters in PVC, and quality rinse valve |

| RO C3 Flow rate: Up to 35 m³/h | Horizontal pressure pipes of steel coated with polyethylene. 8" membranes. Centrifugal pumps in stainless steel, prefilter of 1 µ, control panel with conductivity meter and automatic quality control, flowmeters in PVC, and quality rinse valve |

| RO C4 Flow rate: Up to 60 m³/h | Horizontal pressure pipes in steel coated with polyethylene. 8" membranes. Centrifugal pumps in stainless steel, prefilter of 1 µ, control panel with conductivity meter and automatic quality control, flowmeters in PVC, and quality rinse valve. Plants are designed according to customer demand |

Reverse osmosis units are used for production of demineralized water without use of hydrochloric acid and sodium hydroxide. Among other things, the units are used in boiler houses, district heating plants, hospitals, dialysis centres, and laboratories, for process water in the pharmaceutical industry and the chemical industry, as well as in connection with humidification plants. RO units remove pyrogenics as well as bacteria and cause no wastewater problems. The units remove up to 90% of the organic substances and retain 98-99% of the salt in the water.

Advantages

Storage and handling of acid and lye are avoided. The units are extremely space-saving thanks to the compact design. The plants are of high quality, need minimum maintenance, and the reliability of operation is very high.

Unit description

Flow rates for standard modules: 50 l/h - 60 m³/h. RO plants are either produced as standard modules or custom-made according to requirements. The units comprise selected components of high quality. They are automatic with electronic quality monitoring.

Custom-made plants

There are many possibilities of custom-made solutions. Nearly all parametres and components can be varied and combined. EUROWATER has great experience in producing RO pipe systems in many types of materials such as PP, PE, PVDF, and stainless steel. The foundation and frame, too, can be delivered in stainless steel.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production