RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

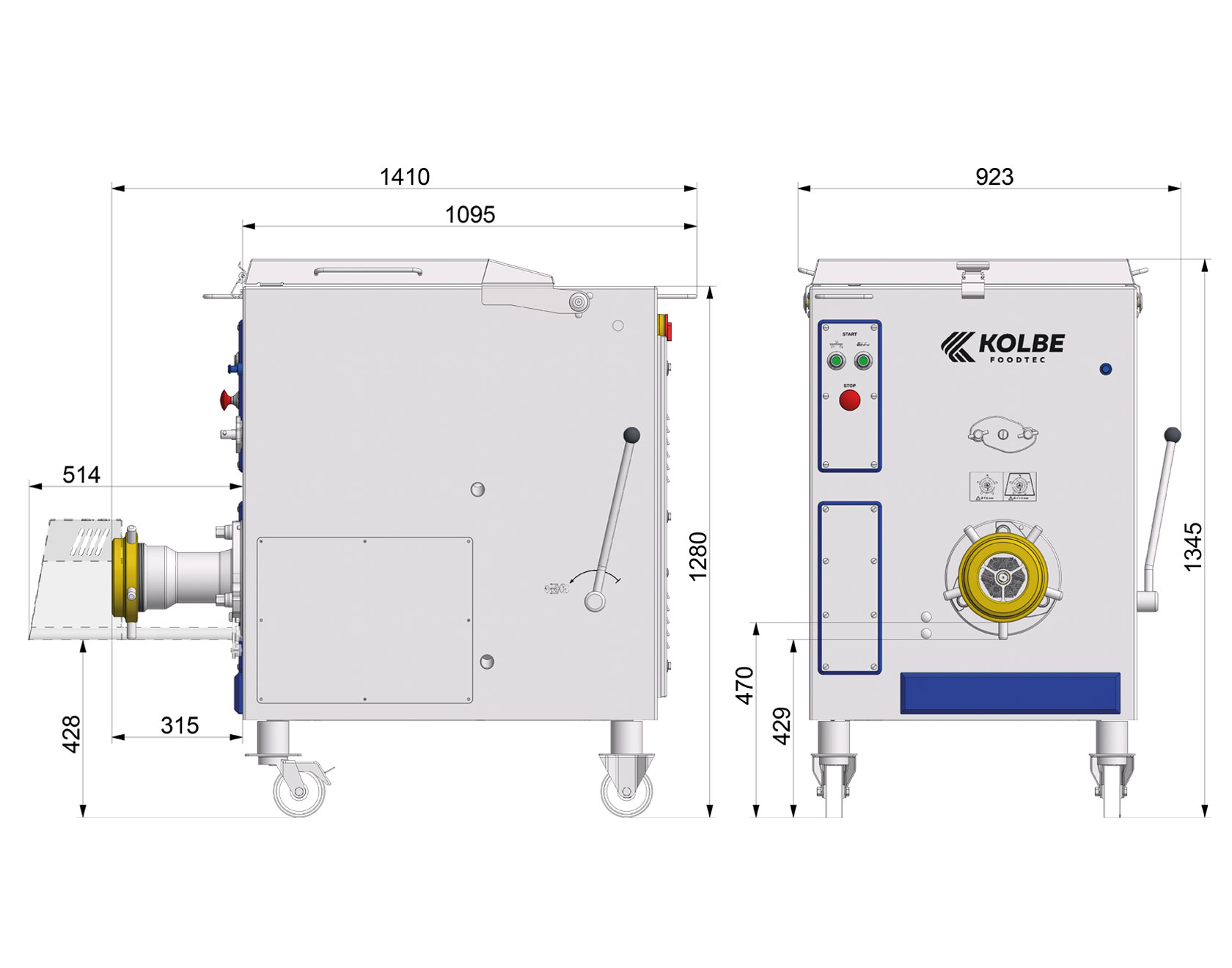

Grinder with mixer KOLBE MW130-120

Grinder with mixer KOLBE MW130-120

| GENERAL TECHNICAL DATA | |

| Output per hour | approx. 2000 kg (3 mm) |

| Power | 10 + 1.1 kW |

| Machine dimension W x D x H | WDH - 923 x 1410 x 1345 |

| Weight | approx. 535 kg |

| Hopper | 120 Liters |

This model is one of the bigger mixer mincer that are suitable for portioning. Bigger parts up to a temperature of -8°C the mincer processes effortlessly due to its bigger cutting system and dimension of the worm. The MW130-120 is used wherever the pretension to the batch size requires a hopper of 120 liters.

The mixer mincer is optionally available with a stepless speed regulation and therefore not only suitable for the processing of minced meat, but also for the production of cooked sausage.

| Options | Description |

| Outlet protection cover | |

| Motor voltage | 400 V , 3 ph |

| Cutting system Unger 5-pieces | Unger E130 |

Recommended goods

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production