RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

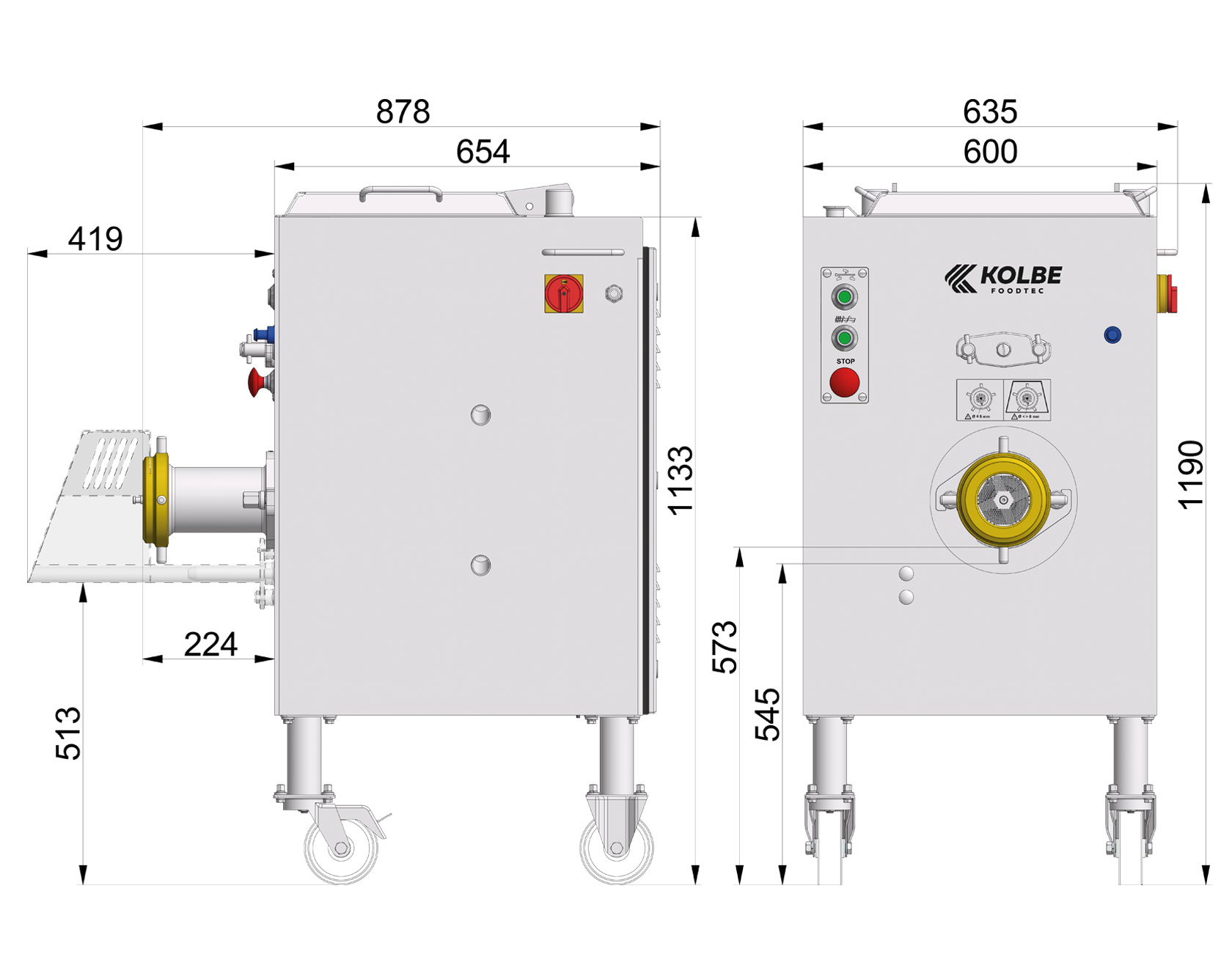

Grinder with mixer KOLBE MWK32-45

Grinder with mixer KOLBE MWK32-45

| GENERAL TECHNICAL DATA | |

| Output per hour | approx. 950 kg (3 mm) |

| Power | 3 (+0,37) kW |

| Machine dimension W x D x H | 635 x 876 x 1190 mm |

| Weight | approx. 260 kg |

| Hopper | 60 litters |

The starting model for the low contact erhöhung aus. processing of minced meat. The compact mixer mincer is best suitable to replace the use of stuffi ng mincers and to produce minced meat in small quantities.

The MWK32-45 model is equipped with an Enterprise E32 cutting system (L&W), a 3 mm hole plate with a hub and four slots and also one knife.

Like all Kolbe Foodtec mixer mincers, this model stands out with its excellent output and cutting performance while minimal rise in temperature.

| Options | Description |

| Outlet protection cover | |

| Motor voltage | 400 V , 3 ph |

| Cutting system Unger 5-pieces | Enterprise32 |

Recommended goods

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production