RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

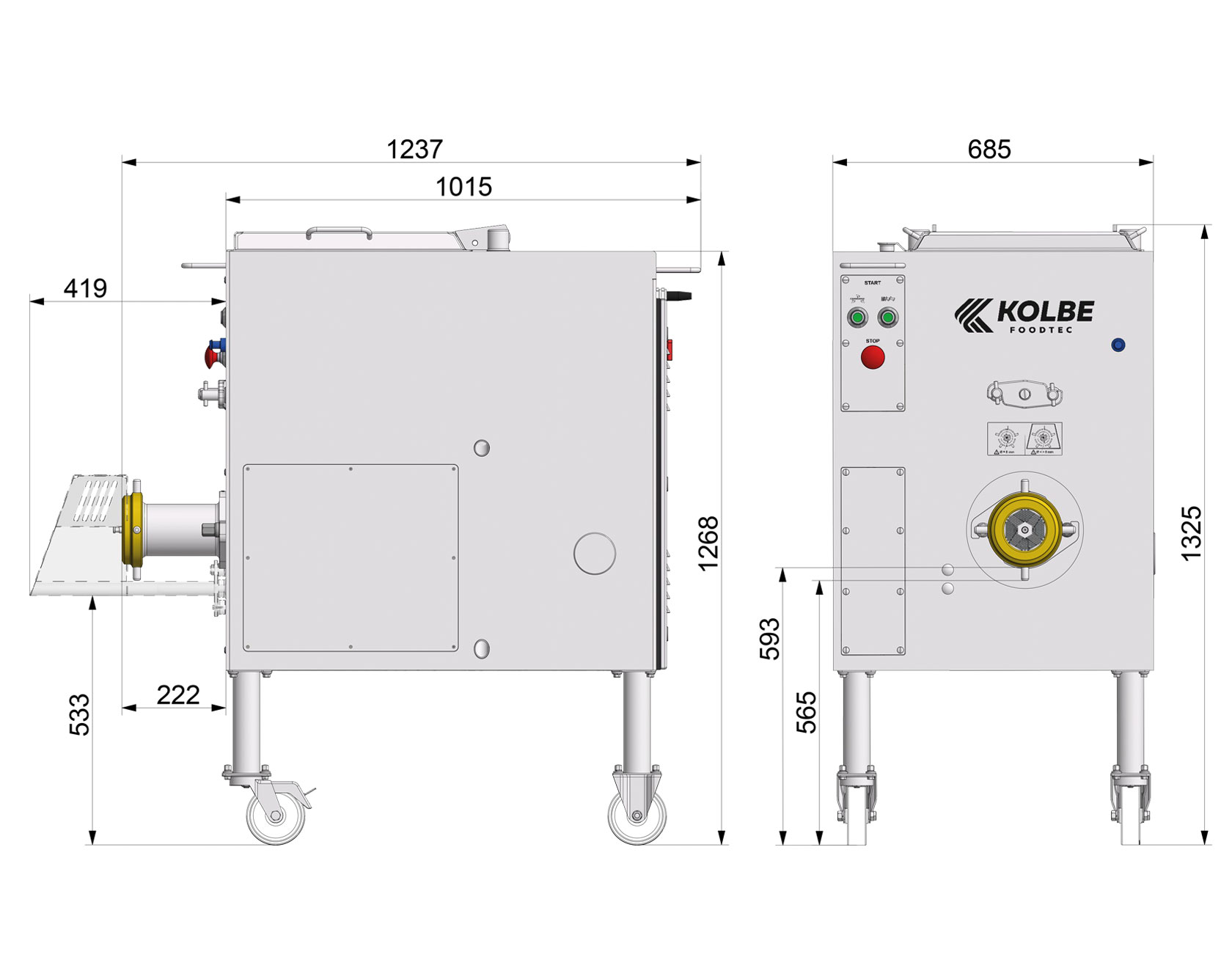

Grinder with mixer KOLBE MWK32-80

Grinder with mixer KOLBE MWK32-80

| GENERAL TECHNICAL DATA | |

| Output per hour | approx. 1050 kg (3 mm) |

| Power | 4.0 (+0,75) kW |

| Machine dimension W x D x H | WDH 685 x 1237 x 1325 |

| Weight | approx. 260 kg |

| Hopper | 80 litters |

The starting model for the connection with a Kolbe Foodtec PM150 portioning device. The mixer mincer has a compact drive with a good basis performance and is therefore highly suitable for portioning. The machine processes parts of fresh meat up to max. -1°C effortlessly. The MWK32-80 has a hopper of 80 liters but can be optionally equipped with a cooled version and is therefore highly suitable for the production of kebab.

The MWK32-80 finds its use in middlesized stores, the meat wholesale and bigger butcheries.

| Options | Description |

| Outlet protection cover | |

| Motor voltage | 400 V , 3 ph |

| Cutting system Unger 5-pieces | Enterprise E32 |

Recommended goods

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production