BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

Horizontal vacuum massaging tumblers MAGNUM II

Horizontal vacuum massaging tumblers MAGNUM II

| GENERAL TECHNICAL DATA | |

| Drum volume | 770-1540 lt |

| Massaging capacity | 600-1200 kg |

| Rotational speed (continuously adjustable) | 3-24 rpm |

| Cooling aggregate version "COOL" | 2,2-3,6kW |

| Vacuum pump | 7,5-11kW |

| Weight | 1660-1960 kg |

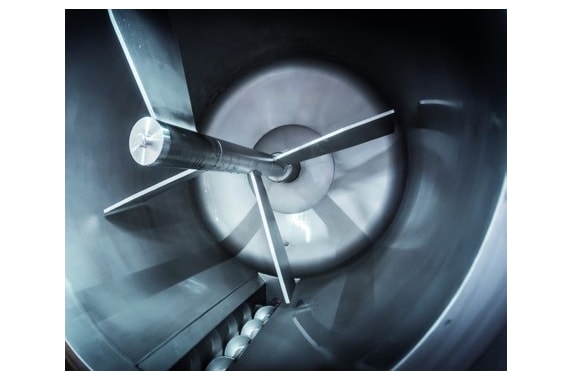

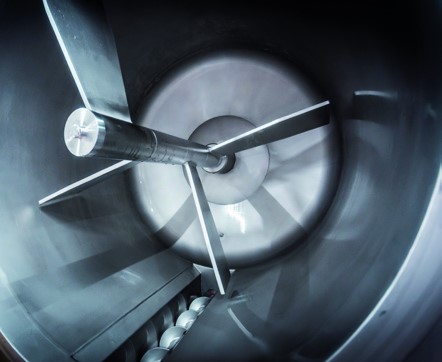

The processing of small meat parts often requires an intensive massage, ensuring the optimal and homogenous brine absorption within the product. The intensive massaging units from Inject Star comply with this requirement and represent the perfect solution for the massage of small ham parts. Thanks to the special massaging paddles as well as the unique spiraled screw situated at the container's bottom, a continuous movement of the products during the production process is assured. Due to the reverse moving directions of paddles and screw, the brine is perfectly massaged into the product and completely absorbed. The result is not only a particularly intensive protein activation but also a high water-binding ability as well as an optimal cohesion of the raw products.

Hygienic design - Thanks to the large lid opening at the front side, the massaging container of the IM series from Inject Star can be completely opened. So there is free access to the complete interior, which can be cleaned easily. Even the special massaging paddles as well as the spiraled screw can be pulled out with little effort for cleaning purposes. The result is not only the fulfilment of highest hygienic standards but also the almost residue-free production.

Control

Thanks to the modern and user-friendly "ISC-X10" touch screen computer control all relevant production parameters can be easily set and controlled.

Massaging paddles

Thanks to the special massaging paddles, which ensure an optimal distribution of the products within the container, a particularly intensive massaging effect is achieved. This leads to enormous time-savings of up to 80 percent during the production process, compared to other traditional massaging units.

Spiraled screw

For the quick and easy unloading of the IM massaging units, It ensures the uncomplicated and computer-controlled transport of the products to the outside and possible valuable product residuals or losses are avoided.

Cooling system

Thanks to the serial container jacket insulation as well as the glycol cooling the massaging units of the IM series guarantee an optimal processing temperature - independent of the unit's location and evironmental temperature. While the IM-770 already includes an integrated cooling system, all other massaging units from version IM-1540 onwards dispose of an external cooling aggregate, which is connected via a cooling circuit. Alternatively, there is the possibility to integrate a heat exchanger if there is an existing in-house cooling available.

Loading

The loading of the intensive massaging units from Inject Star is carried out via vacuum suction.

Unloading

The unique spiraled screw transports the products towards the container opening and guarantees and easy and residue-free unloading of the massaged meat, for instance into a standard trolley (200 l) for the further processing.

Advantages

- Intensified massaging effect

- Shortened massaging time by up to 80 percent compared to other traditional massaging units

- Large lid opening

- Quick and easy cleaning

- Avoidance of product residuals and valuable losses

- Hygienic design.

| Options | Description |

| Computer controlled load cells | For weight of the product control |

| Production data acquisition | Recording and traceability of essential production parameters |

| Vacuum filling container | The small meat parts can be sucked together with the spices and additives directly out of an optional mobile vacuum filling container (VC). Adapted to the different versions of massaging units of the IM series, this vacuum filling container is available in various sizes |

| Industry 4.0 |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production