RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

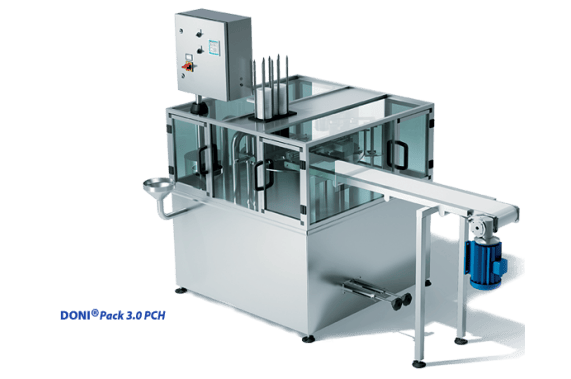

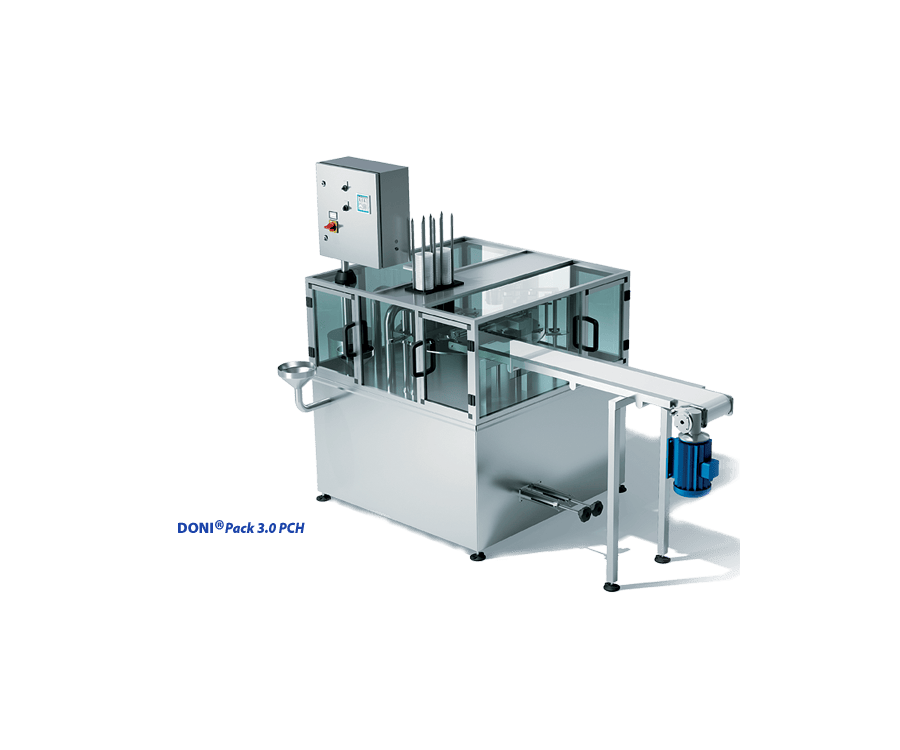

Packaging module | DONI®Pack 3.0 PCH

Packaging module | DONI®Pack 3.0 PCH

| GENERAL TECHNICAL DATA | |

| Production capacity: | 2,600 to 3,200 packs/hour, depending on the product |

| The power supply: | 3 kW |

| The air consumption: | 700 l/min with a pressure of 6 bar |

| Length, mm: | 1 600 |

| Width, mm: | 1 400 |

| Height, mm: | 1 950 |

DONI®Pack 3.0 PCH is specifically designed for the packaging of:

- processed cheese;

- cream cheese

The process is fully automated and is monitored by sensors which will stop the module if any of the manufacturing stages fail.

The packaging is plastic with different shapes and weight, depending on the specific requirements of the customer.

The weight is regulated in two ranges:

-volume doser from 50 g to 200 g;

-volume doser from 100 g to 500 g.

Dimensions: (Dimensions may vary according to size of the packs).

The module is supplied with a buffer tank whose modifications and volume depend on the specific packaged product.

DONI®Pack 3.0 PCH module requires CIP cleaning.

| Options | Description |

| Optional extras: | - aseptic panelling with sterile air inserted; - UV lamp; - jet printer; - automatic positioning of additional lid; - exit conveyor belt for the finished packaging; |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production