BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

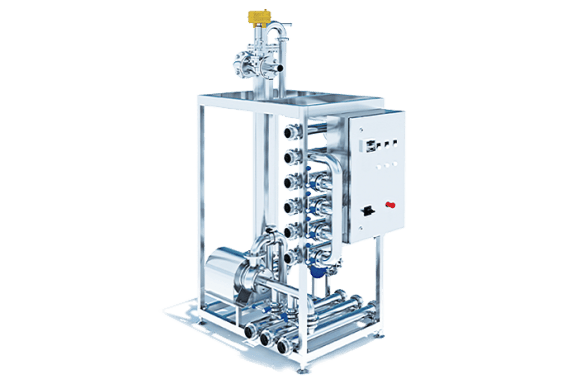

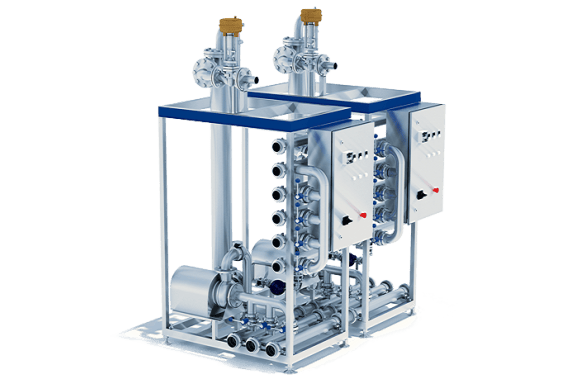

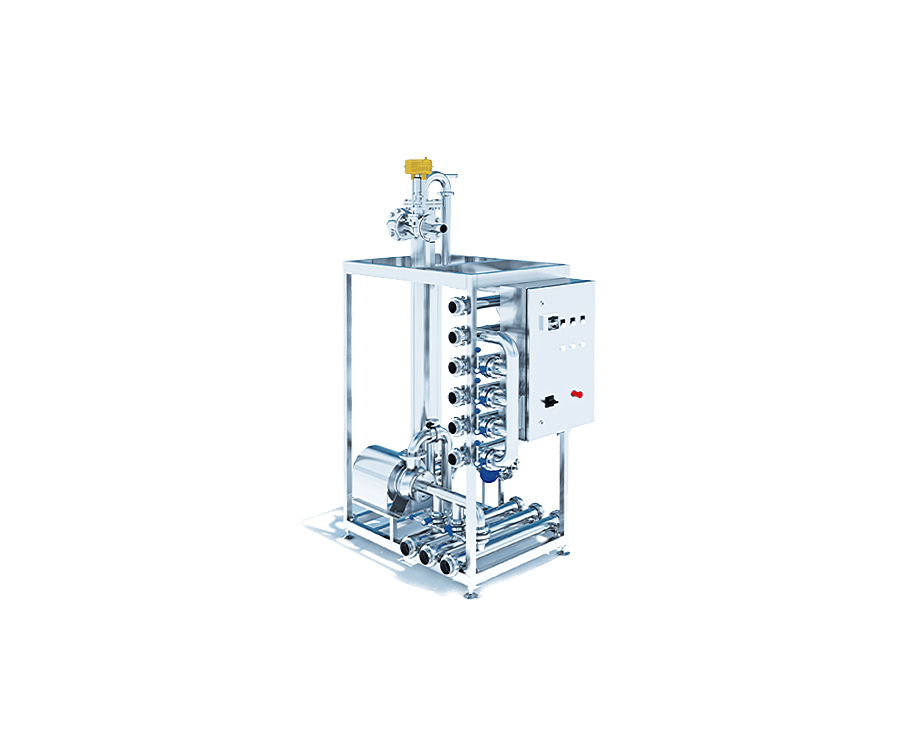

Cleaning-In-Place module | DONI®Pro CIP M 25

Cleaning-In-Place module | DONI®Pro CIP M 25

| GENERAL TECHNICAL DATA | |

| Productivity /pressure 4 atm/ l/h 3 000 ÷ 27 000 | 3 000 ÷ 27 000 |

| Electrical power, kW: | 6 |

| Air consumption (pressure 6 atm), l/min: | 110 |

| Steam consumption (pressure 3 atm), kg/h: | 700 |

| Length, mm: | 1 900 |

| Width, mm: | 1 430 |

| Height, mm: | 2 230 |

The module is designed for cleaning in a closed line with circulation through the cleaning solutions storage tank. It has three main programs. The cleaning cycle is semi automated and it does not require a high level of automation in the production sectors /HLA/. Cleaning systems with up to 4 modules can be constructed with

DONI®Pro CIP M. Every module services 12 lines in 24 hours. Different time and temperature parameters are set for each line (only time and temperature) depending on the contamination. The cleaning of two or more lines can be performed if there is sufficient output and pressure.

The solutions in the storage tank have to be prepared before the work begins. The preparation is done through the recirculation line and includes: Increasing the solutions temperature to 45 – 50 °С and adding detergents until the necessary concentration in the storage tanks is reached.

DONI®Pro CIP M is installed on a platform, compact and hydraulically tested in factory conditions. It has a rotary pump, a balance tank, a plate or tubular heat exchanger and sensors for conductivity, temperature, flow and pressure. It also has regulating valve and shut-off valve for steam, sanitary manual valves for flow control, control panel.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production