BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

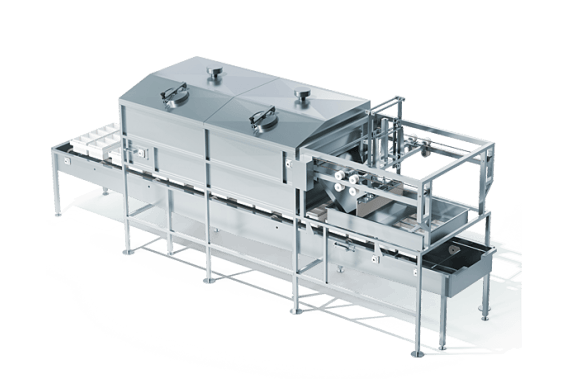

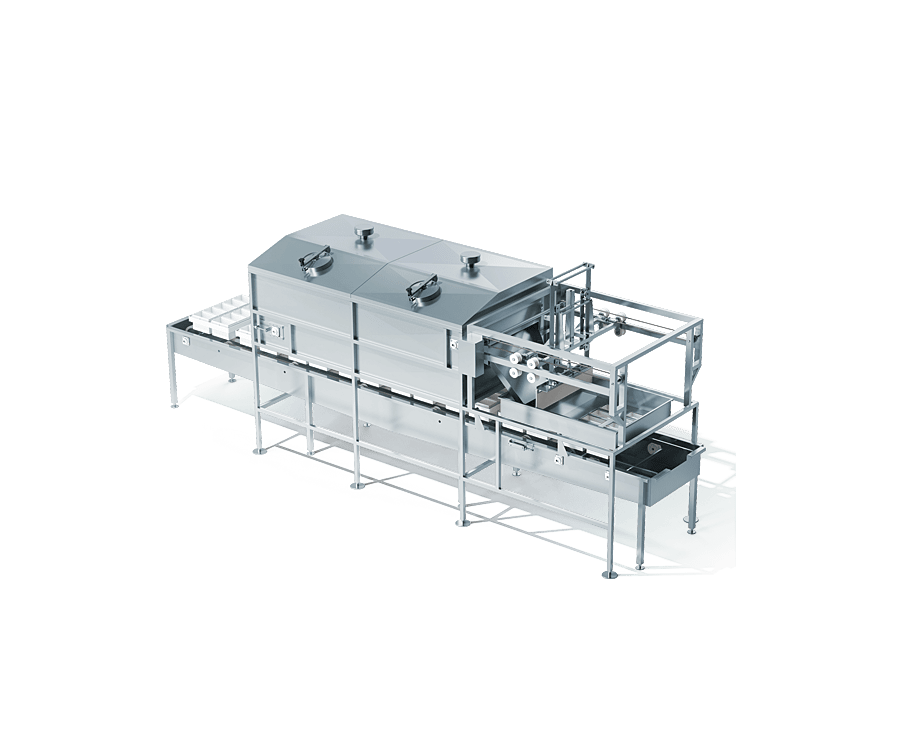

Module for partial draining and filling of moulds | DONI®Draining/Filling

Module for partial draining and filling of moulds | DONI®Draining/Filling

| GENERAL TECHNICAL DATA | |

| Power (kW): | 0,55 /without a conveyor belt/ |

| Length (mm): | 6 100 /with a conveyor belt/ |

| Width (mm): | 1 800 |

| Height (mm): | 2 200 |

| The power supply: | 2.0 kW |

| The air consumption: | 100 l/min. |

| The production capacity: | from 800 kg/h to 1 500 kg/h, depending on the weight of the moulded product. |

| The duration of a cycle: | from 30s to 50 s. |

The module is designed for the partial draining of whey and dosed filling of moulds and block moulds. It is used in the manufacturing of soft cheese, moulded Tvorog and other cheeses. It is offered in two Models: DONI®Draining/Filling MF with manual mould filling and DONI®Draining/Filling AF with automated mould filling.

DONI®Draining/Filling is a fully closed system with a draining belt. The curd-whey mixture is fed through a distributor on the draining belt. Its special construction allows for 85% of the whey to be drained. The belt runs at high speed with the product moving along it in a thin layer. The mixture's temperature should not be lower than 30°С to be able to realise effective moulding. The moulds can be filled manually or automatically through a distribution plate which has the same shaped openings as the mould. The plate is vertically regulated to be able to adjust the weight of the product.

The module is supplied with a conveyor belt for the positioning and moving of the moulds. A rotator, stacker and de-stacker can be supplied upon request.

DONI®Draining/Filling is designed for CIP cleaning.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production