BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

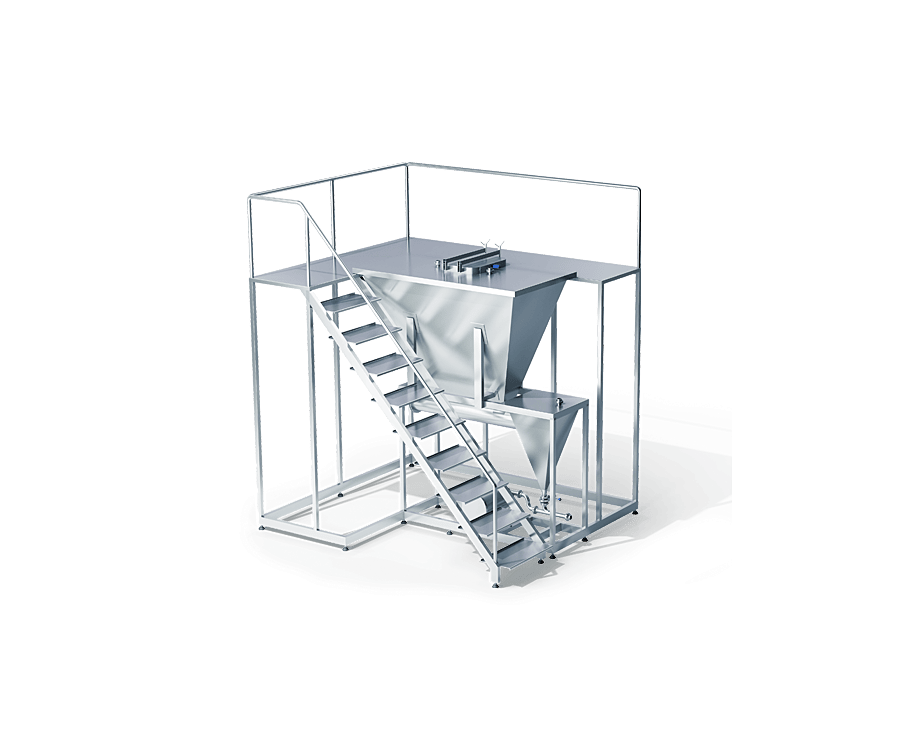

Module for dry added ingredients | DONI®Dry Plus 10

Module for dry added ingredients | DONI®Dry Plus 10

| GENERAL TECHNICAL DATA | |

| The production capacity of the module: | 10 000 l/h of finished product with a power supply of 6,5 kW |

| The volume of the hopper: | 2 m³ |

DONI®Dry Plus 10 is designed for the dosed dissolving of dry additives in milk or for restoring powder milk in the production of yogurt and other dairy products. The dry additives are placed in the hopper of DONI®Dry Plus 10. There is a screw conveyor installed on the base which feeds the dry ingredients evenly towards a 50 l silo with an integrated injector at the bottom (Venturi tube). The liquid (water or milk) where the additives are dissolved is pumped through the injector. The high speed of the flow and the pressure difference at the inlet and the outlet creates a vacuum which sucks the dry ingredients in evenly. The prepared mixture is then fed with or without de-aeration into DONI®Tank for storage and processing.

The maximum saturation of the mixture is 30% dry matter in the whole of the entire mixture. If the process requires a higher content of dry matter the ready mixture is re-circulated. For more effective dissolving of the dry additives DONIDO® recommends the liquid where the additives are added to be heated to 50°С at the inlet of DONI®Dry Plus 10. It should then be cooled for storage at 4°- 6°С at the outlet. For best results DONIDO® installs a vacuum de- aerator after the module for foam removing.

DONI®Dry Plus 10 connects to DONI®Tank, where the prepared mixture is stored. Three tanks are necessary to be able to provide continuous operation.

DONI®Dry Plus 10 will be suitable for CIP cleaning if a second return pump is included. It is suitable for medium and large sized dairy factories.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production