BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

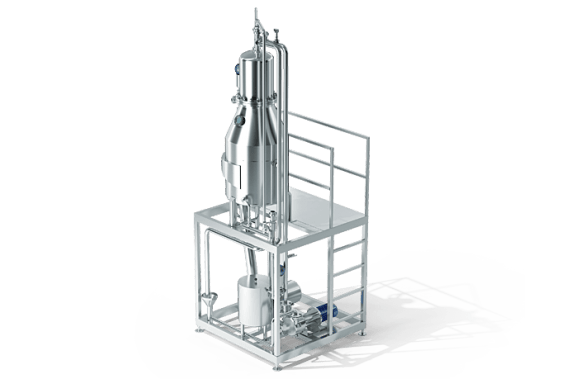

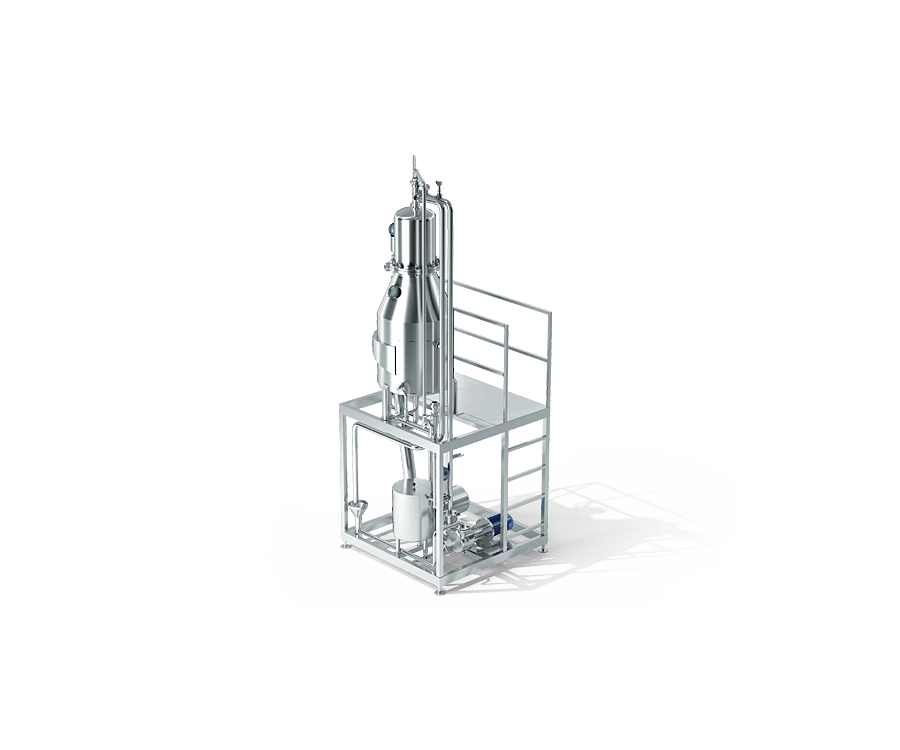

Module for milk vacuum de-aeration | DONI®Deair

Module for milk vacuum de-aeration | DONI®Deair

| GENERAL TECHNICAL DATA | |

| Models | DONI®Deair 5.0 from 1 000 to 5 000 l/h with power supply 3 kW; DONI®Deair 10.0 from 5 000 to 10 000 l/h with power supply 5,5 kW; DONI®Deair20.0 from 10 000 to 20 000 l/h with power supply 11 kW; DONI®Deair 30.0 from 20 000 to 30 000 l/h with power supply 17 kW. |

DONI®Deair is an integrated module for vacuum de-aeration and it operates together with DONI®Therm. The milk which has been heated to 68°С flows tangentially in a tank under vacuum of 0,7 atm.These conditions cause intensive evaporation where finely dispersed air separates (evaporates) from the product. The vapour condenses in the condenser and returns. The air separation improves the operation of DONI®Therm and prevents the build up of carbon deposit in the high temperature section. It also prolongs the period between two cleaning cycles.

When DONI®Deair operates without a condenser then a significant part of the product's water content evaporates. This part can reach 2%. If that occurs the module effectively removes the undesired milk odour and improves the quality of the final product.

The module is designed for CIP cleaning.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production