BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

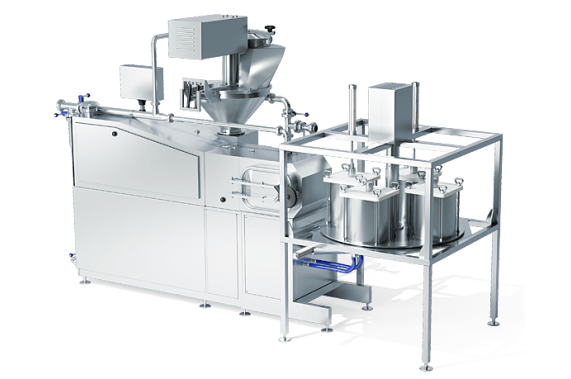

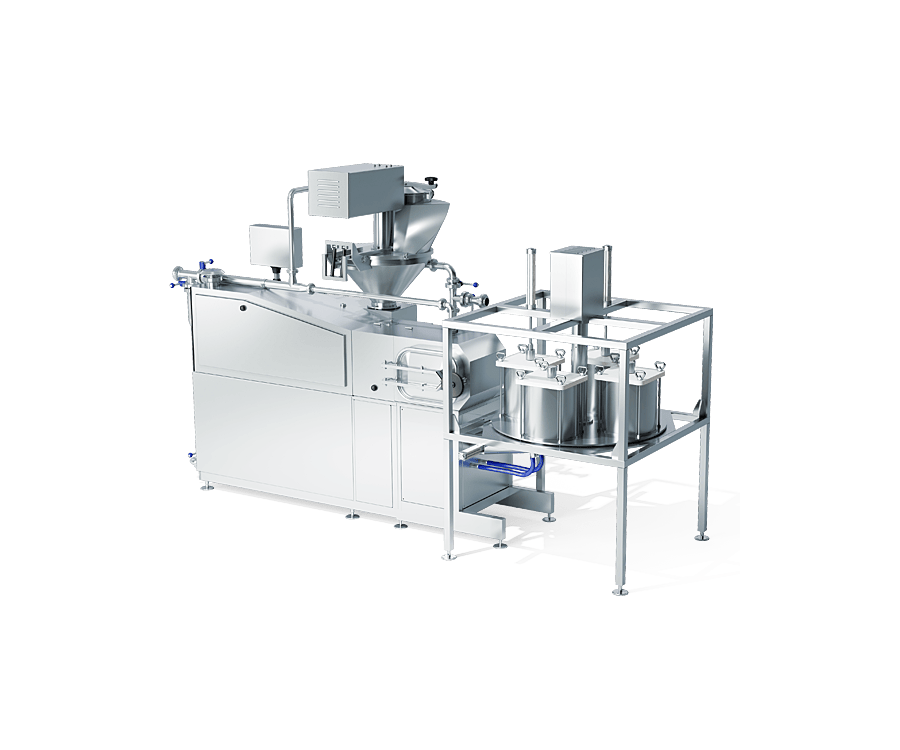

Curd cooking module | DONI®Plastformer 2.0

Curd cooking module | DONI®Plastformer 2.0

| GENERAL TECHNICAL DATA | |

| The maximum production output: | up to 2 000 kg/h finished product |

| Production output: | from 1 000÷2 000 kg/h, depending on the integrated DONI®Former |

| Power supply: | 5.5 kW without the power of DONI®Former |

| The steam consumption: | 250 kg/h |

DONI®Plastformer 2.0 is integrated in the production lines for kashkaval, pizza cheese, suluguni and other pasta filata which require a dense structure and lower water content. It is usually used for moulding into different shapes from 5 000 g to 9 000 g. Cheddared /pH 5,2÷5,4/ curd blocks with sizes ranging from 150 mm to 150 mm and a length from 300 to 500mm are fed in the module. They are cut with a disc cutter into pieces around 3mm thick and enter a specially constructed U pipe along with the brine which is heated to 72-76°С. During the movement of the mixture in the U pipe the temperature of the curd pieces increases to 60 - 63°С and they become soft and malleable. At the same time they undergo a brining process absorbing the dissolved salt. The quantity of the absorbed salt depends on the concentration of the hot brine.

The unused brine is drained through the perforated rotating drum for reuse. In the drum the curd pieces stick to one another and the initial homogenisation of the cooked curd begins. The final homogenisation and the filling of the moulds are performed in DONI®Former module which which is an integrated part of DONI®Plastformer 2.0. It determines the productivity and the geometrical shape of the finished product. This does not include the power required for DONI®Former.

The possible configurations of DONI®Plastformer 2.0 are illustrated on fig. 2. Their production output can be found in the information regarding DONI®Former.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production