BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

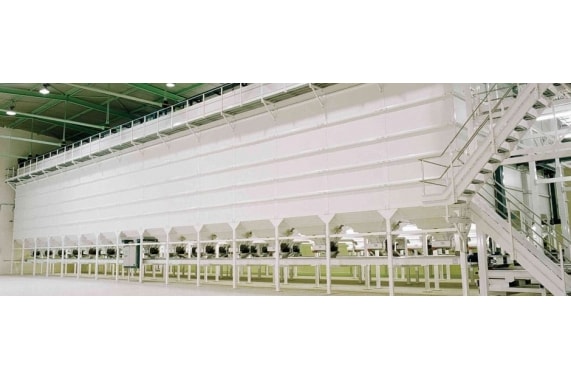

Storage plants Cusinato

Cusinato offers Silos manufactured with an exclusive system: a robust metallic weight bearing structure designed to carry product loads of particularly high weight, also considering the feeding systems (Belt or Bucket Conveyors). Cusinato has also developed an exclusive system for the fixing of panels, which prevents the formation of cracks due to the inevitable natural expansions and temperature changes of the environments in which they are installed, avoiding product leaks or stagnation.

In this way the panelling is relieved of the “weight bearing” function and ensures the non-deformability of the silo and the maximum degree of hygiene in each cell.Automatic loading systems for storage plants, equipped with bucket conveyors (or, on special request, with mobile belts), ensuring full flexibility in the routes and load cell combinations, as well as from different production lines.Stainless steel spiral lowerator for each cell (different versions, diameters and capacities), developed and perfected in order to accompany and deposit the products in the loading stage without damaging them, by fully exploiting the cell capacity.Extraction system by vibration for the even unloading of all standard pasta shapes, ensuring the complete emptying of the cells. Complete with adjustable sliding gate and flow deflector, both available in different versions: operated manually or automatically with remote control and with different sections/flows.Electrical control panel with PLC equipped with HMI (touch screen) operator interfaces or computerised (one or more PC workstations) that enables you to monitor the entire loading and unloading process, by programming and automating the loading of the silos and the sending of the product to the packaging machines. The computerised system is available with standard and/or customised functions.Computerised system equipped with instruments that monitor the activities of the plant and which ensures the management and reliability over time (operation events log, maintenance management, management operator passwords, production reports, traceability, statistics, alarms history, etc.).

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production