BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

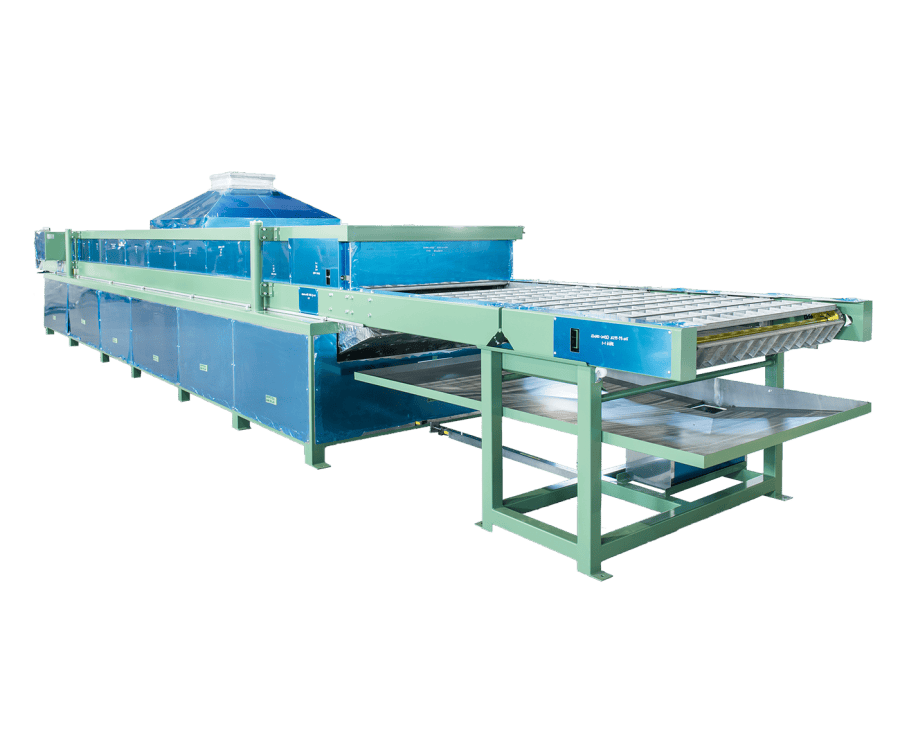

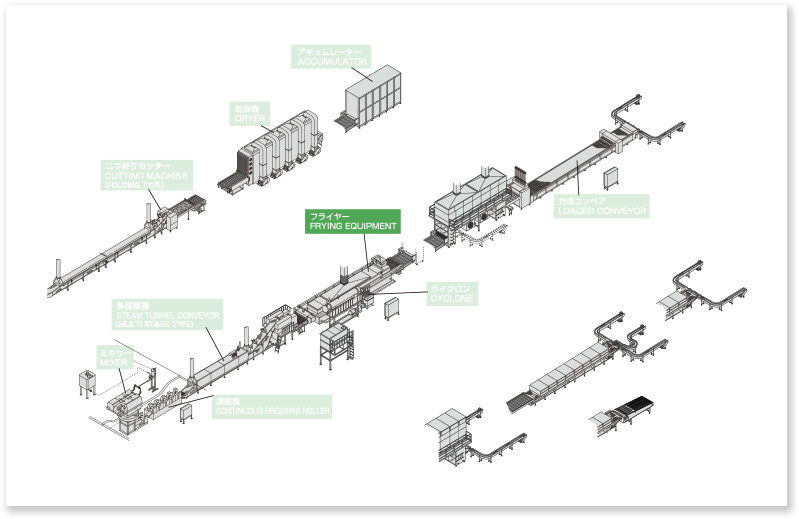

Continuous frying tunnel for instant noodles FUJI

Continuous frying tunnel for instant noodles FUJI

| GENERAL TECHNICAL DATA | |

| Capacity | from 500 kgh |

| Temp of oil | from +90 to +160C |

The portions cut into one and stacked in two layers are loaded onto a belt conveyor with baskets (square or round shapes) after the belt with forms is dipped into hot oil in the frying tunnel. Portions of noodles usually contain from 30 to 50% moisture, but by passing them through hot oil at +140-160 ° C for 1-2 minutes inside the frying tunnel, the moisture content drops to 14-15%.

At the same time, the starch gelatinization state is fixed.

The Noodle Frying Tunnel produces "fried noodles" for instant cooking by adding boiling water to a cup and waiting for 3 minutes. To dry portions of noodles by the standard classical method without frying, an automatic drying tunnel is used and in this case noodles are produced for standard cooking 4-6 minutes

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production