RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

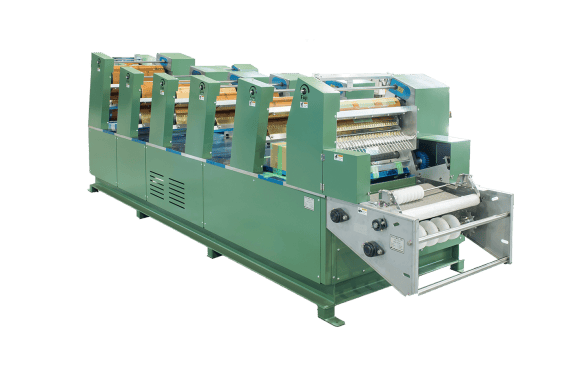

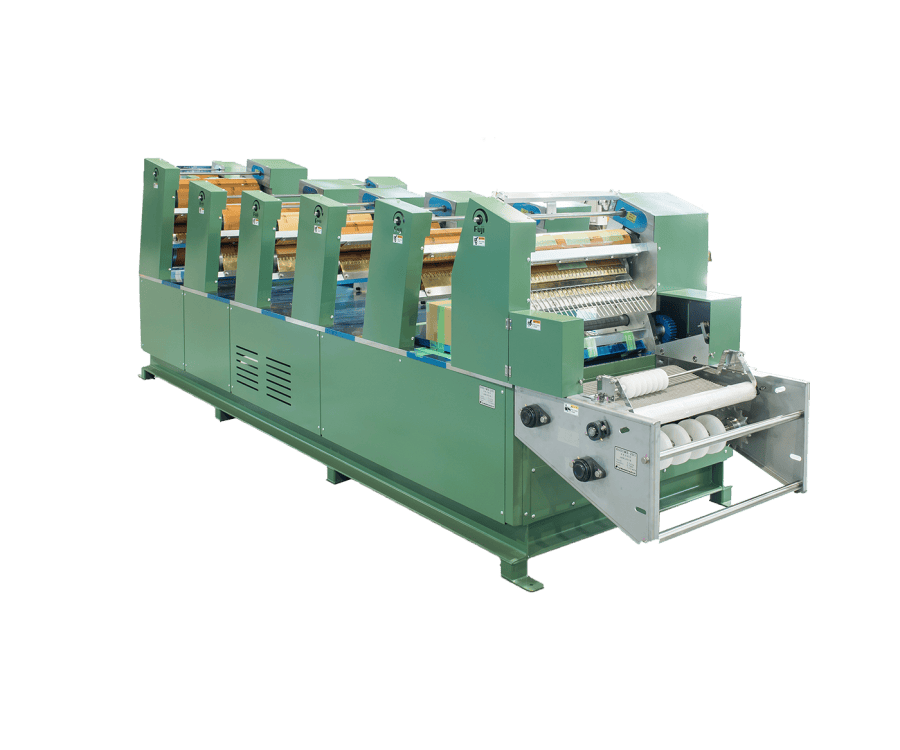

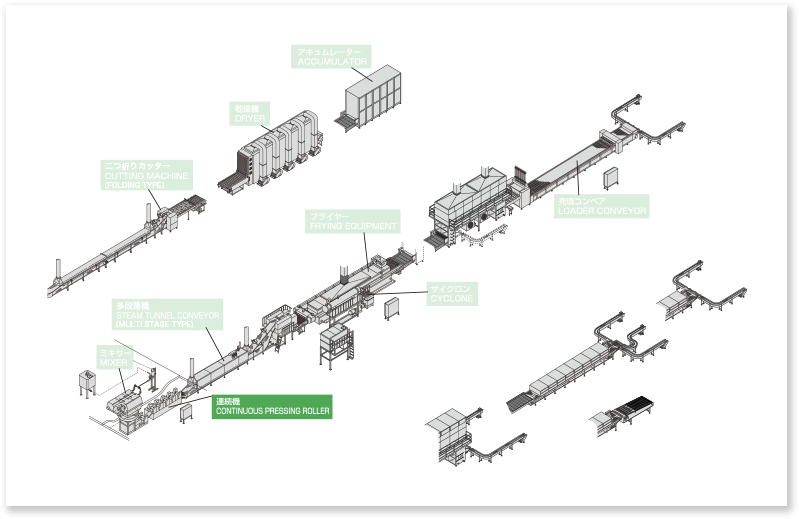

Continuous sheeter for instant noodles FUJI

Continuous sheeter for instant noodles FUJI

| GENERAL TECHNICAL DATA | |

| Capacity | from 500 kgh |

| Rollers quantity | 6 to 14 groups |

Fully automatic continuous machine adapted for automatic washing after work

- The dough is pressed out with the help of rows of calibrator shafts

- Automatic dough web sagging control function

- The position of the dough belt is maintained by detecting a belt loosening between the rollers by a sensor and automatically adjusting the number of revolutions of each calibration group.

- Automatic dough conveyor

- Automatic feeding of dough at the beginning of production and when changing batches of products. (There is no risk of hands getting caught in the shafts.)

- Automatic shaft clearance adjustment

- The roll gap adjustment, which was done manually, is adjusted with one touch on the touch panel.

- In addition, data can be set for each product, and the gap between rollers is automatically adjusted to the set value.

- Shaft clearance display

- Digital display of the gap between each calibration group.

- Noodle belt thickness measurement and automatic adjustment function

- Measuring the thickness of the tape coming out of the final roll.

- If there is a difference between the thickness of the dough and the set value, the gap between the rollers is adjusted automatically.

- Noodle scrap detection device

- The camera can detect trimmings and foreign matter on the noodle dough and remove the layer of noodles automatically (trim detection unit).

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production