BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

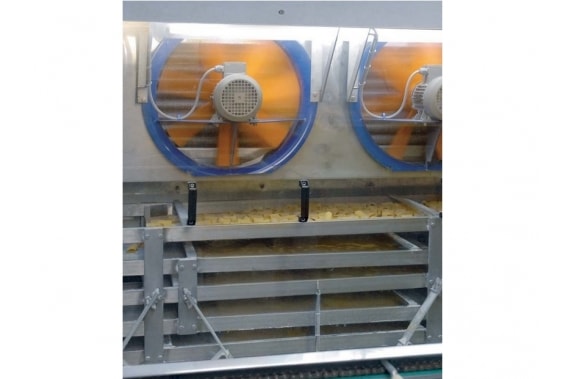

PRE-DRYER TP 200

PRE-DRYER TP 200

| GENERAL TECHNICAL DATA | |

| Capacity | 300 kgh |

| Layers | 5 |

| Dimensions w x d x h | 940 x 2900 x 1400 mm |

| Installed power | 12,0 kW |

This machine is essential to first surface treatment of the product in order to avoid sticking and retain shape, brightness and colour. Suitable for short pasta, gnocchi, ravioli, tortellini and cappelletti. The different regulation systems which this machine is equipped with enable the highest versatility and use in all fresh or dry pasta production fields. Built in stainless steel with insulated panels, dismountable for easy cleaning and maintenance.

The first pre-drying phase is important to retain shape and colour of the product: this occurs thanks to correct ventilation and efficient heating device

All models are equipped with the following:

- Electronic variator for vibration intensity

- Regulation of treatment temperature and regulation of cycle duration

- Linking ventilation flow with modular ventilation system hot/cold

- Upon demand special constructions are made

Upon demand

- Automatic loom-feeding machine mod. MT suitable for looms measuring 120 x 60 cms. with automatic feeding device for collection and spreading of short pasta from pre-dryer.

- Structure in stainless steel with stock of max. 20 looms and motorized forwarding.

- Electric control panel prearranged for running with nesting machines and automatic loom stacker mod. IA 32.

- Model for fresh pasta are completely washable.

Models TP 200 are available for functioning with hot water exchanger, power from 20.000 Kcal per hour.

*Maximum output depends on type of product

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production