BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

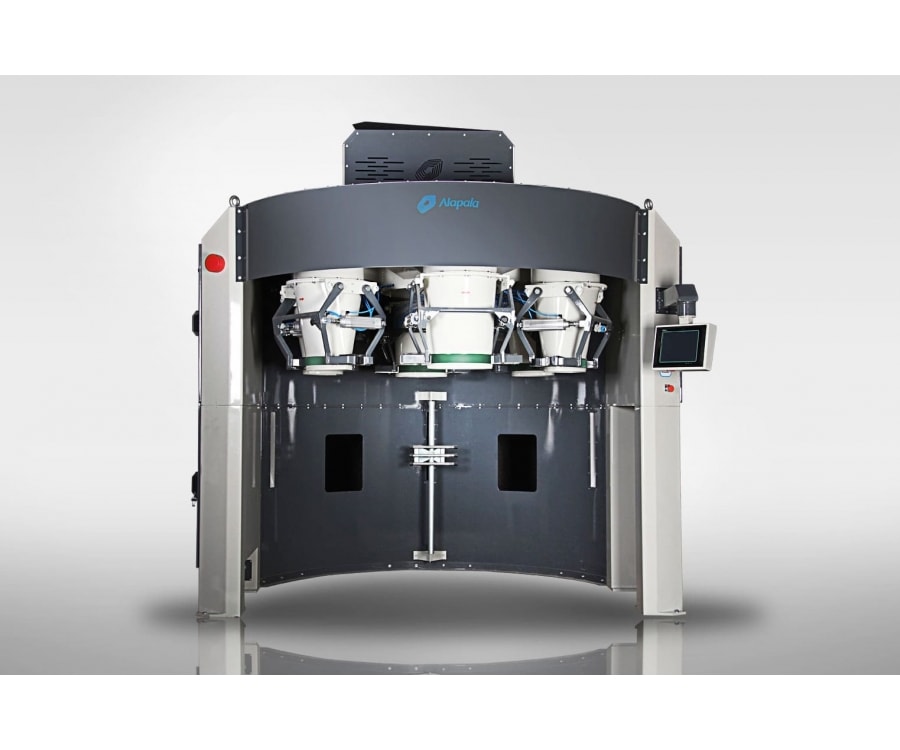

Carrousel Packing Machine | CTMA

Carrousel Packing Machine | CTMA

| GENERAL TECHNICAL DATA | |

| Quality | High |

| Efficiency | High |

| Extraction | High |

| Capacity | High |

| Life | Long |

| Precision | High |

| Hygiene | Maximum |

| Security | Maximum |

| Using | Maximum simplified |

| Periodical maintenance | Low |

| Delay to change the spares parts | Low |

| Energy consuption | Low |

| Noiseless | Yes |

| Design | Perfection and aesthetic |

It is used to bag the granular and processed products in 10 kg, 25 kg, and 50 kg PP bags at high capacities.

Working Principle

The weighing process is made by one or two weighing units, which are isntalled on weighing machine. The machine would have 4 (four) or 6 (six) spouts per capacity. During weighing process, the weighing unit holds the sack and waits till a warning comes from “hold switch” and do not open the covers. When a warning arrives the product is allowed to run and filling process is carried out. When the spout platform turns the new free spout arrives at weighing station while the filled bags arriving shaking station for proper handling, meanwhile the operator places an empty sack on the free spout and the filled sack is sewn consequently on the sewing band conveyor. The speed of machine is regulated in accordance with product and the length of sack.

| Options | Description |

| Application fields | Food industry Flour and semolina mills Feed mills Dry fruit plants Other food industry Chemical industry Painting made plants Plastic made plants Deterging made plants Wooden industry Nonferrous product industry |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production