BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

Chain Conveyor | KZKI

Chain Conveyor | KZKI

| GENERAL TECHNICAL DATA | |

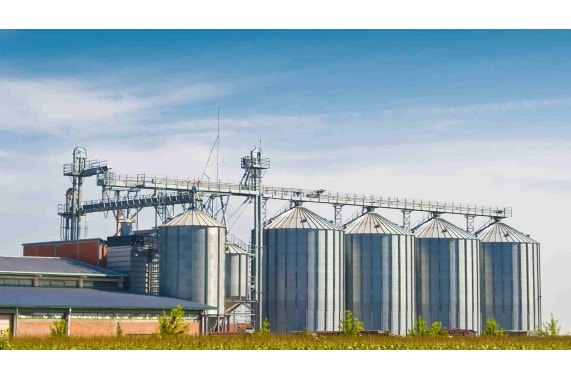

| Application fields | At food industries Flour, semolina and feed mills Shelled peanuts factories Sugar and salt plants Cocoa factories Soybean and rice plants Raw material, grain, cereal storage silos and stores Other similar food processing plants |

It is used mainly to convey all types of bulk material in the food industry.Adjustable by using ZT series of chain installation

Structure

An enclosed, rectangular cross - section, made of steel casing is furnished with an endless chain equipped with flights.

Working Principle

The lower chain section moves along the bottom of the steel casing and conveys the materials. The return part of the chain is guided along the central rail. The chain runs around a sprocket at the outlet end and around and idler at the inlet end. The material and chain travel along at a uniform speed. The product is dropped through the chain at the outlet and flows out of the conveyor. The design of the chain lets several inlets, which can be arranged along the entire length of the conveyor. It is also possible to install outlet gates, which can be manually and remotely controlled.

The chain

The most important and working part of a chain conveying system is “chain”. In order to obtain the necessary high tensile strength and wear resistance of the chain, it is manufactured in a special forging and hardening process.

For special application at food processing and handling, the stainless steel chain can be supplied.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production