BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

Rapid defrosters for fish and seafood “COLDWAVE+”

Rapid defrosters for fish and seafood “COLDWAVE+”

| GENERAL TECHNICAL DATA | |

| Capacity per hour | 150 to 13000 |

| Inlet blocks temperature | -18С |

| Output blocks temperature | -1/-3С |

| Electrical consumption | 7 to 105 kW |

| Salmon filet | Block 8 kg From -20°C to -3 / -1°C in 35 min |

| Shrimps | 2 bags 500 g/each in cardboard box From -20°C to -4 / -1°C in 15 min |

Thanks to the rapid and gentle Radio Frequency tempering process, the physical, biological and nutritional integrity of fish and seafood are preserved at best, thus ensuring the product freshness and healthiness.

Different species of fish and seafood, whole, H&G, fillets, loins, steak/chunks, shell-on or peeled can be RF defrosted:

- squid,

- calamari,

- octopus,

- scallops,

- mussels,

- sardines,

- salmon,

- tuna,

- swordfish,

- shrimps, prawns, crawfish, lobsters,

- cod,

- pollock,

- hake,

- pangasius,

- halibut,

- catfish, etc.

The treatment can be performed on IQF products or blocks.

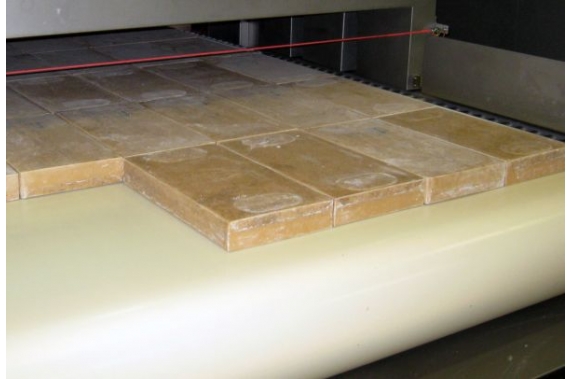

The multi-position upper electrode system and the wide conveyor belt allow to process a wide range of sizes and weights: from few kg to 30 kg and from few cm to 23 cm high (standard configuration). Upon request, the machine can be customized to process bigger and heavier blocks.

Thanks to the characteristics of the RF field and the different types of conveyor belt available, the product can be processed packaged (in PE film/liner or bag, open or vacuumed, paper film, PE + carton, PP crates or trays, etc.) or “naked”.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production