BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

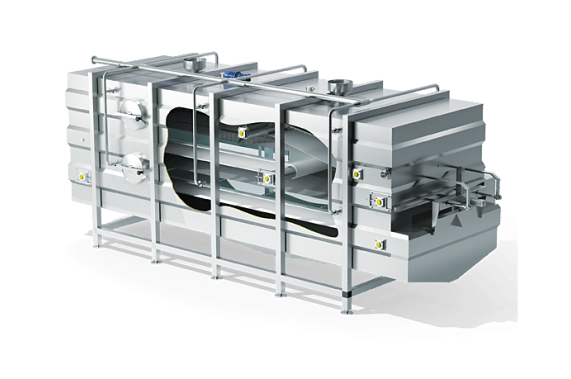

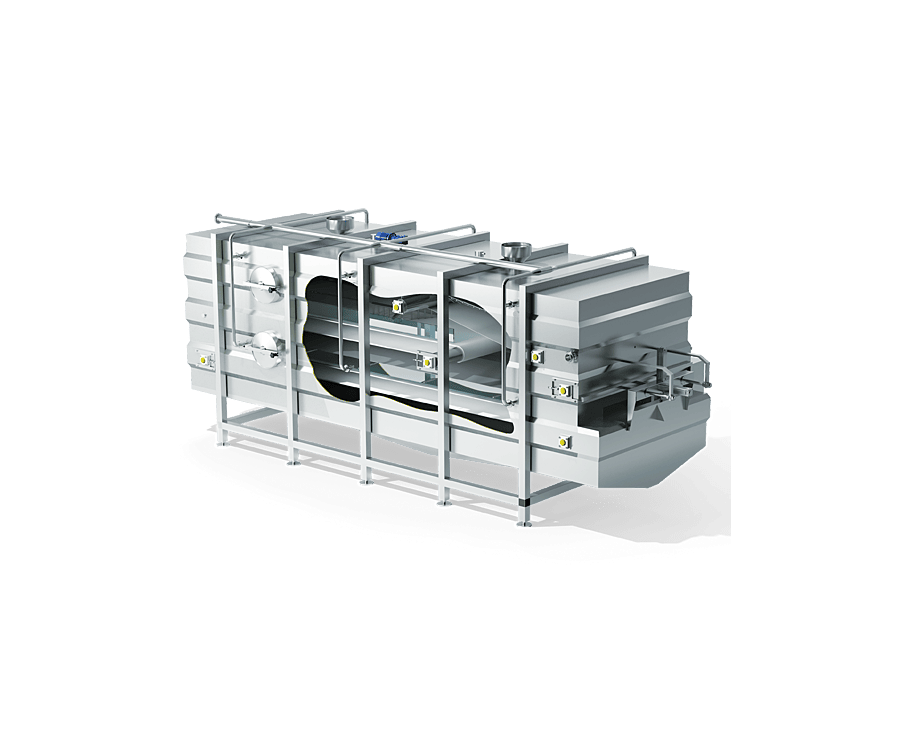

Module for continuous draining and cheddaring | DONI®Cheddarmatic

Module for continuous draining and cheddaring | DONI®Cheddarmatic

| GENERAL TECHNICAL DATA | |

| Productivity: | DONI®Cheddarmatic 0.5 - 500 kg/h during a continuous process; DONI®Cheddarmatic 1.0 - 1 000 kg/h during a continuous process |

| Power supply: | DONI®Cheddarmatic 0.5 - 4 kW; DONI®Cheddarmatic 1.0 - 7 kW |

| Steam consumption: | DONI®Cheddarmatic 0.5 - 150 kg/h; DONI®Cheddarmatic 1.0 - 250 kg/h |

| Air consumption /6 atm/: | DONI®Cheddarmatic 0.5 - 250 l/min; DONI®Cheddarmatic 1.0 - 250 l/min |

The module is designed for the draining of whey and the cheddaring of the curd in a controlled environment. DONI®Cheddarmatic is a fully closed system with three draining lines. The curd-whey mixture is fed through a distributor on to the first draining line which has the highest position. Its special constriction allows for 85% of the whey to be drained. The product moves in thin layers at high speed. The product is transferred on to a second line with a slower speed where the operation (motion) continues and the thickness of the layer is 80 to 100 mm. At the beginning of the line there is a scarifier for final draining. After turning and falling on to the third line the finished product leaves the module. At the outlet a pneumatic guillotine cuts it into blocks which are then transported to DONI®Plastformer or to DONI®Stretchformer for processing.

The cheddaring time is regulated at a range of 40 to 60 min. The temperature in the inner space is automatically maintained at 40°С. The module is delivered ready for operation with: Servicing man holes with internal lighting, level sensors; spray balls connected with a collector; a temperature sensor installed in one of the cutting-stirring tools; level sensors; control panel; scarifier and pneumatic guillotine situated at the outlet.

DONI®Cheddarmatic is designed for CIP cleaning.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production