BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

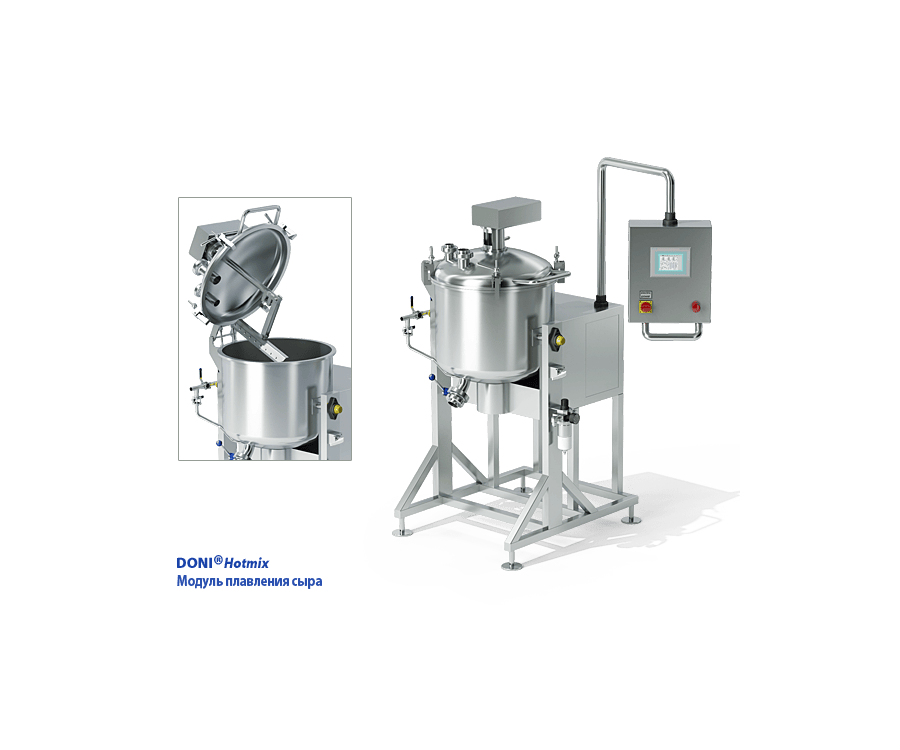

Module for processed cheese | DONI®Hotmix

Module for processed cheese | DONI®Hotmix

| GENERAL TECHNICAL DATA | |

| Power supply the knife, kW: | 5 |

| Power supply of the paddle, kW: | 0,37 |

| Steam consumption , kg/cycle: | 80÷120 (depending on the cycle) |

| Air consumption, l/min: | 60 |

| Ice water consumption, l/min: | 700 |

| Geometric volume, l: | 147 |

| Operating volume, l: | 100 |

| Length, mm: | 1 450 |

| Width, mm: | 1 100 |

| Height, mm: | 1 880 |

DONI®Hotmix is designed for the production of different types of processed cheese. The main ingredient (crumbled cheese) and additives are added through the upper lid. The finished product is discharged through a valve at the elliptical bottom. It is possible to incline the unit for better discharge. The mixture is heated indirectly. The unit has a double wall filled with water, where steam is injected at a pressure of 0,3 MPa.

The maximum steam pressure of the unit is 0,3 MPa which is regulated by a safety valve. The working temperature is regulated automatically and can reach a maximum temperature of 95°С max . As an option there is a possibility to inject clean steam of 0,2 MPa directly into the unit in order to speed up the process and to control the water content. The maximum steam pressure in the main unit should be 0,2 MPa, which is regulated by a safety valve.

Homogenisation of the mixture is carried out by a single or double knife installed in the centre at the bottom of the unit. The processing time is 10 to 20 min, depending on the heating method. The rotation frequency is slowly regulated at between 1 500 and 3 000 min ⁻¹.

There is a rotating paddle with rotation frequency of 22 min⁻which is installed on the top lid to clean the inner walls during operation. DONI®Hotmix is equipped with a control panel which allows the programming of different recipes and controls all of the manufacturing parameters during processing. A vacuum system may be supplied as an option.

DONI®Hotmix is designed for CIP cleaning.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production