BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

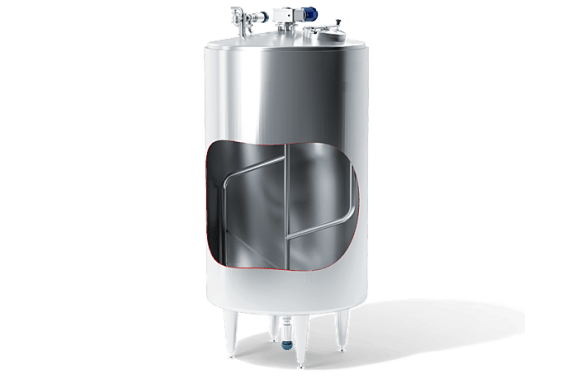

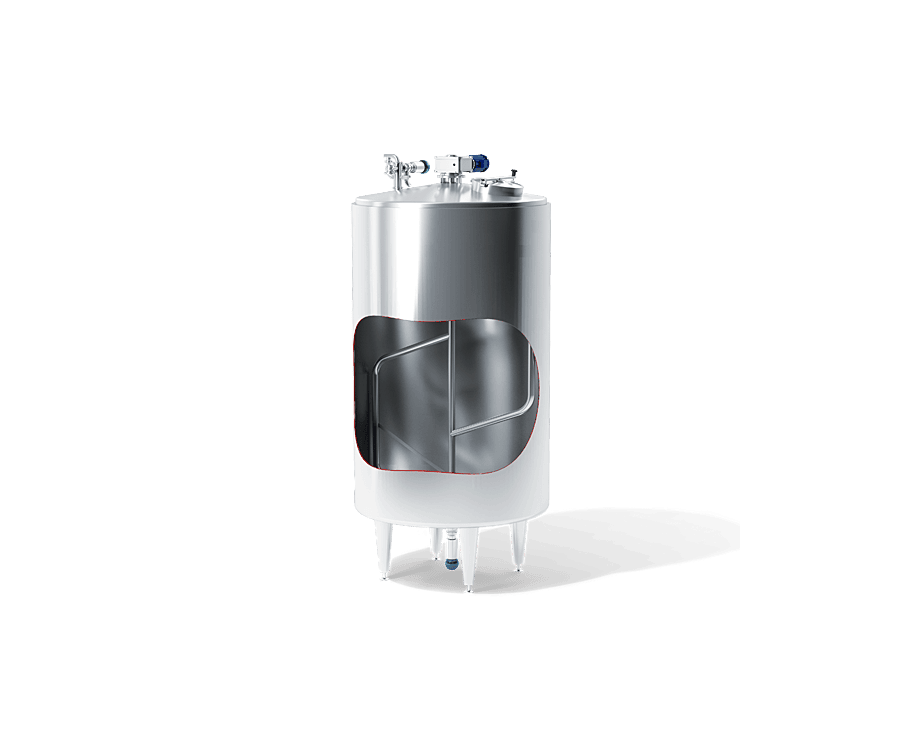

Process tanks for fermentation | DONI®Process

Process tanks for fermentation | DONI®Process

| GENERAL TECHNICAL DATA | |

| Laboratory Volume L Power kW |

50; 100; 150 0,37 |

| Semi-industrial /for manufacturing sectors that produce industrial yeast Volume L Power kW |

300; 600; 800; 1000 0,37; 0,75; 0,75; 0,75; 0,75 |

| Industrial medium Volume L Power kW |

1600; 2000; 2500; 3000ж 4000 0,75; 0,75; 1,1; 1,1; 1,5 |

| Industrial high capacity Volume l Power kW |

5000; 6000; 10000; 15000; 20000 1,5; 1,5; 3,0; 3,0; 4,0 |

DONI®Process is a vertical cylindrical tank with insulation and welded sheath, closed with two cone shaped bases. On the upper base there are: a manhole, an aseptic module and a gear motor of the stirring mechanism. The specifically designed stirring mechanism ensures best results and protection of the coagulum. If during fermentation or later the temperature cycle needs corrections, the module is supplied with heating-cooling elements and an autonomous system for slow heating. A valve for taking samples is installed in DONI®Process. The valve can be sterilised. The DONI®Process frame requires CIP cleaning. The standard order of volumes manufactured by DONIDO® are:

For the manufacturing of yogurt with hard coagulum DONI®Process is supplied with a propeller stirring mechanism. The standard order is recommended when choosing equipment, however, it does not limit your options. Different options can be negotiated.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production