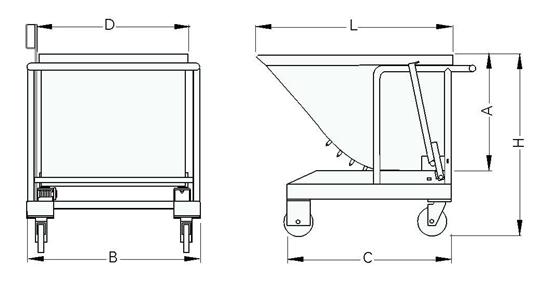

Tilting containers made of stainless steel 304 construction.

Studying customer's requirements

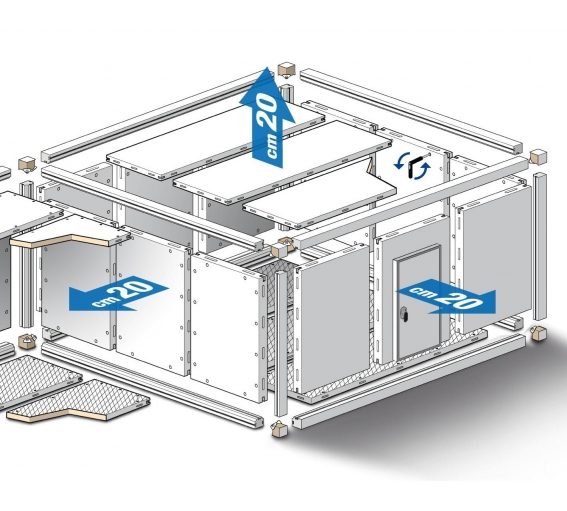

Pre-construction stage of the project (layouts, budgeting)

Civil construction supervision

Equipment supply installation and commissioning

Apply international quality standard and working with customer preferences. Adapt European standard for meat processing and production of sausages and other delicacies all in accordance with Halal standard. Always taking into account local construction requirements with respect to food safety and safe working environment or HACCP aspect of design.