BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

Pneumatic filtration

Pneumatic filtration

| GENERAL TECHNICAL DATA | |

| Cyclone oil separator | Gradation 30 - 15 [µm] Water content 7g / m3 Oil mist concentration high |

| Filtration P and X | Gradation: 5 [µm] Oil content 0.5 mg / m3 Water content: 1.5 - 0.6 g / m 3 |

| Filtration P, X and Y | Gradation 0.01 [µm] Oil content 0.01mg / m3 Water content 1.5 - 0.6g / m3 |

| Filtration P, X, Y and A | Grade 0.01 [µm] Contents oil 0,003mg / m3 Water content 1.3 - 0.5 g / m3 |

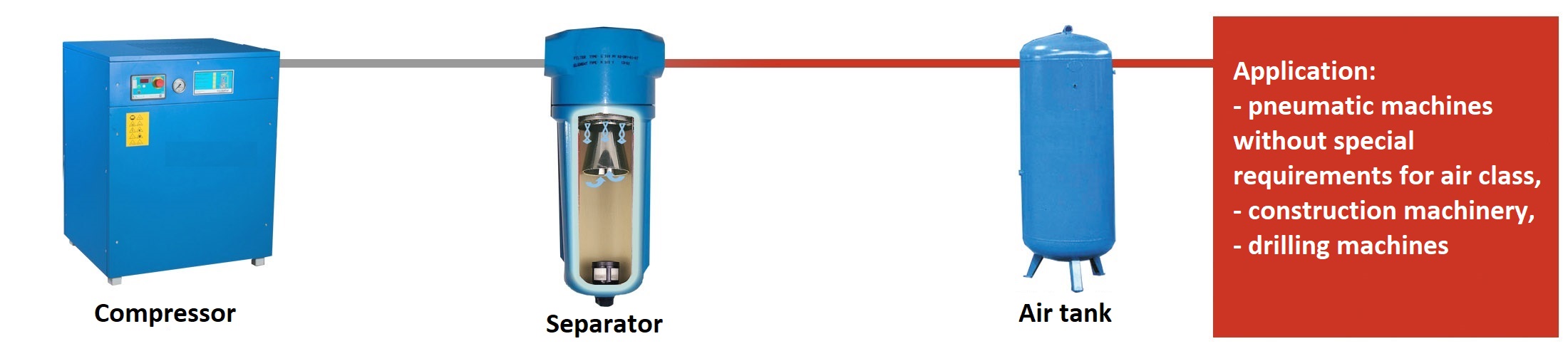

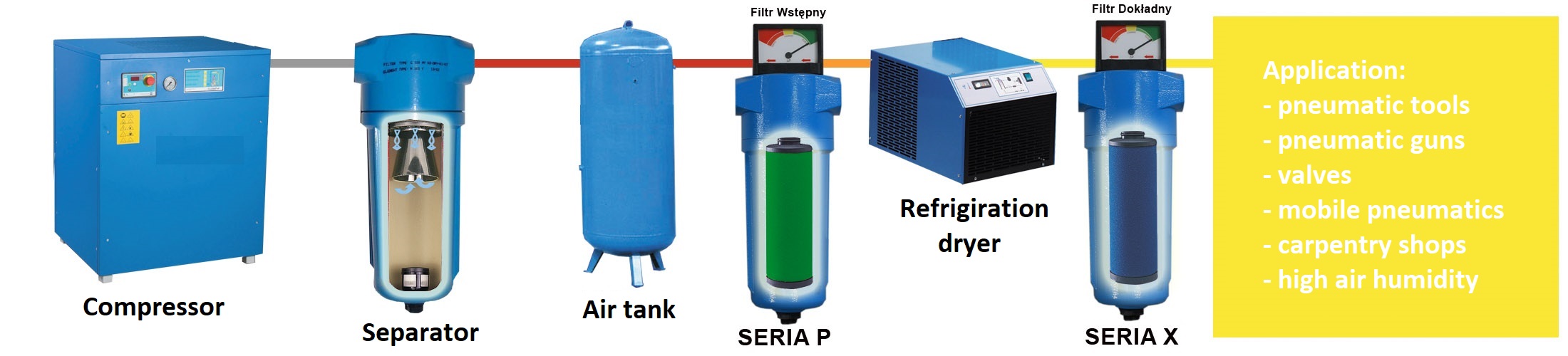

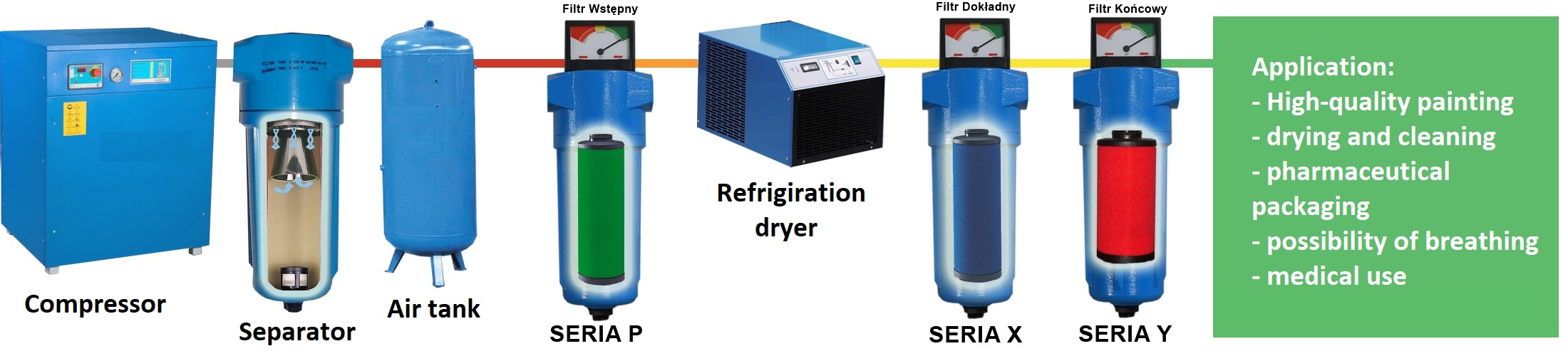

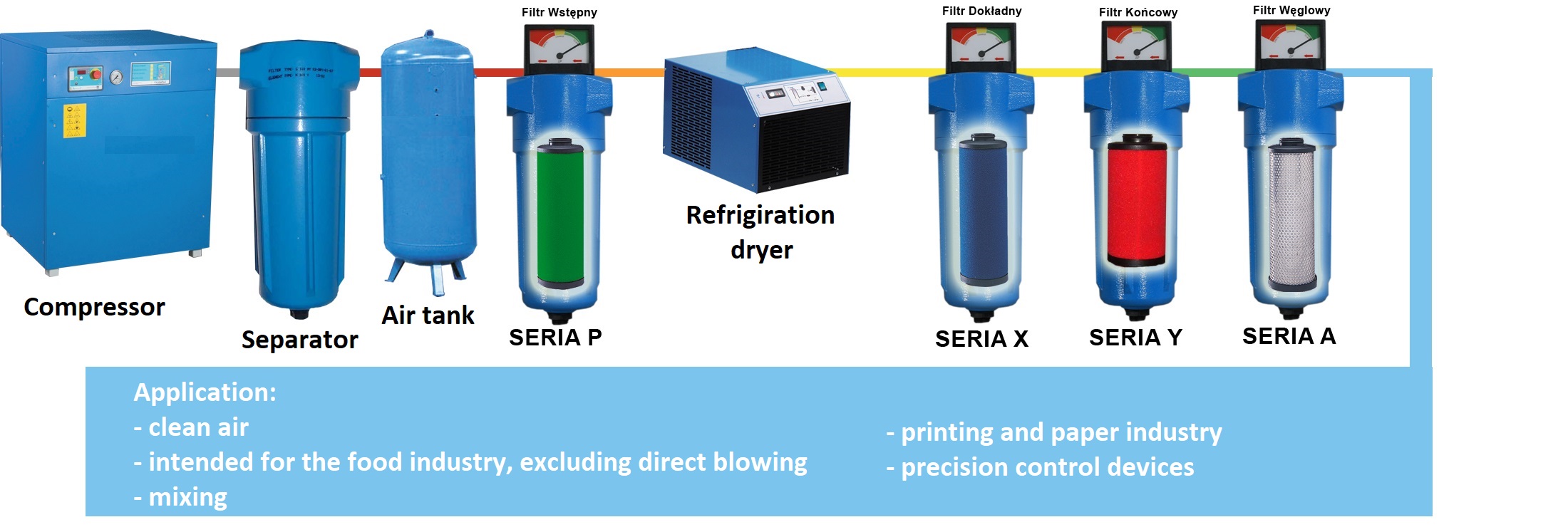

In the late twentieth century, compressed air became, along with electricity, the most widely used energy carrier. They are used in all branches of industry: from pharmacy and the food industry, where air of particularly high purity is required, to heavy industry. Below we present air treatment diagrams. If you have specific information regarding the air quality standard, please CONTACT us

Many pollutants of various origins are involved in the compression process. Depending on the conditions in the compressor room, these are: solid particles, ambient moisture, condensation (water-oil mixture) resulting from the compression process and waste from pipes and other network components. In order to achieve the expected air purity class, the air purity standard at the entrance to a given receiver should be determined. Once we have defined operating parameters, we can adjust air preparation stations to protect the unit and extend the life of the end device. Our systems are designed for almost every industry branch

Efficiency of statement A:

- Gradation: 30 - 15 [µm]

- Water content: 7g / m 3

- Oil mist concentration: high

Efficiency of statement B:

- Gradation: 5 [µm]

- Oil content: 0.5 mg / m 3

- Water content: 1.5 g / m3 to 0.6 g / m 3

Compilation efficiency C:

- Gradation: 0.01 [µm]

- Oil content: 0.01mg / m 3

- Water content: 1.5g / m 3 to 0.6g / m 3

The effectiveness of statement D:

- Grade: 0.01 [.mu.m]

- Contents oil: 0,003mg / m 3

- Water content: 1.3 g / m3 to 0.5 g / m3

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production