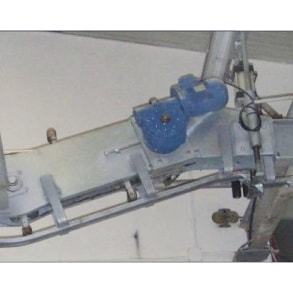

System used to raise the hooks from the level of the cart to the level of the dock rails.

Made up of:

- A telescopic section to join the cart rail with the height change rail.

- An inserter at the entrance to the height change mechanism, powered pneumatically, which allows hooks to enter one by one on the chain.

- Closed 1 'A" chain circuit.

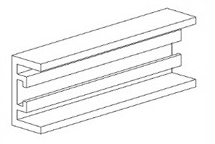

- UPN-60 profile guides.

- Pushers with 4 nylon wheels.

- Electrical control panel.

- Buttons to control the different mechanisms, with stop and start switches.

Made of hot-dip galvanised steel.