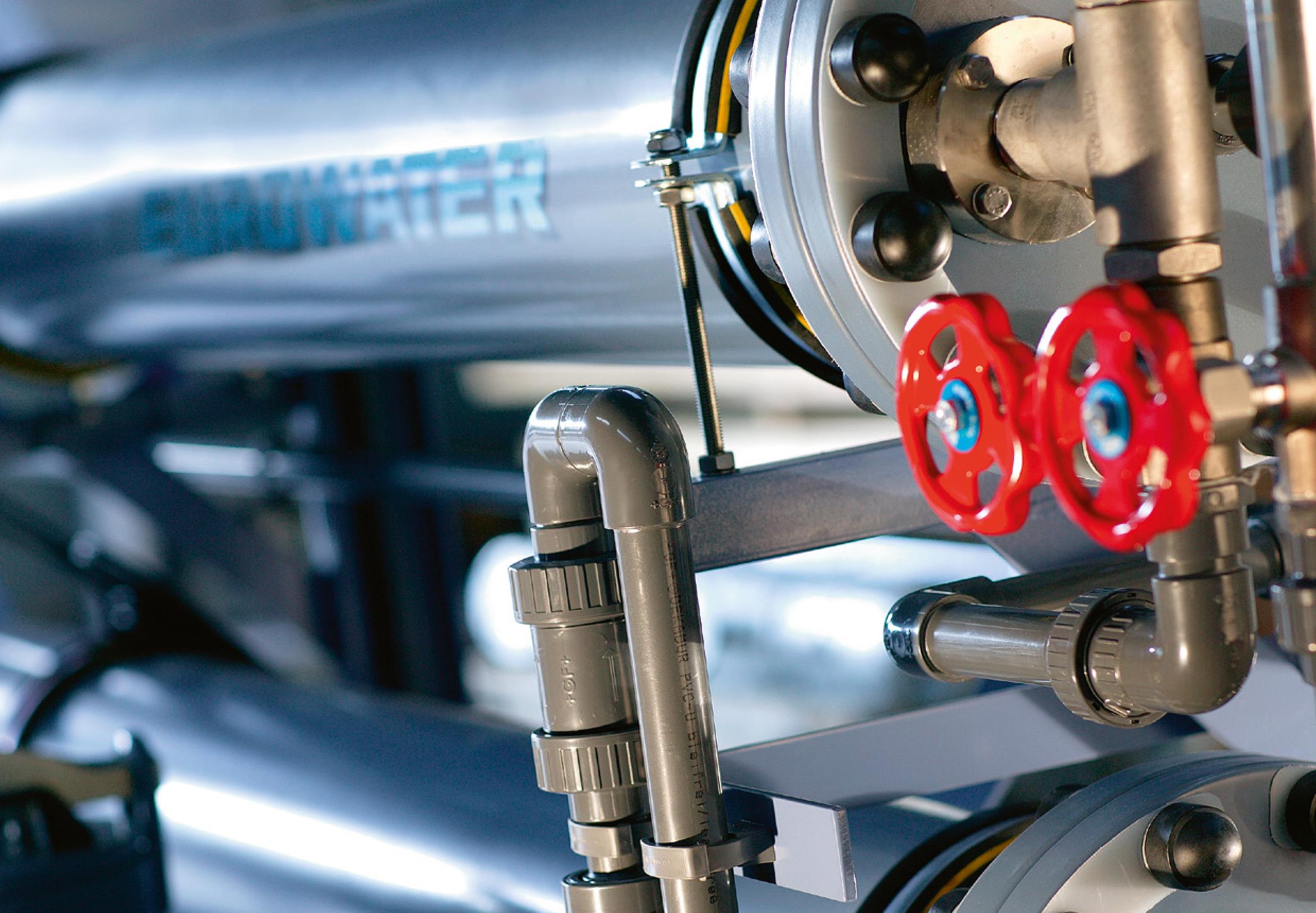

Proper pretreatment of the feedwater to an RO system is an essential factor for unproblematic, long-term operation. Clogging of the membranes by suspended solids, scale-forming minerals, and other impurities have to be prevented by appropriate measures. Hardness minerals can be removed in a softener, suspended solids in a mechanical filter, while free chlorine can be removed in an activated carbon filter. You can select between the following pretreatment options:

- 1-tank softening plant

- 2-tank softening plant, parallel operation

- 2-tank plant with combined filling for softening and removal of free chlorine, parallel operation

Moreover, all units are equipped with a special mechanical filter (strainer) which is reliable and easy-to-maintain. A backflow preventer to separate the unit from the public water system is also standard on all units.