BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

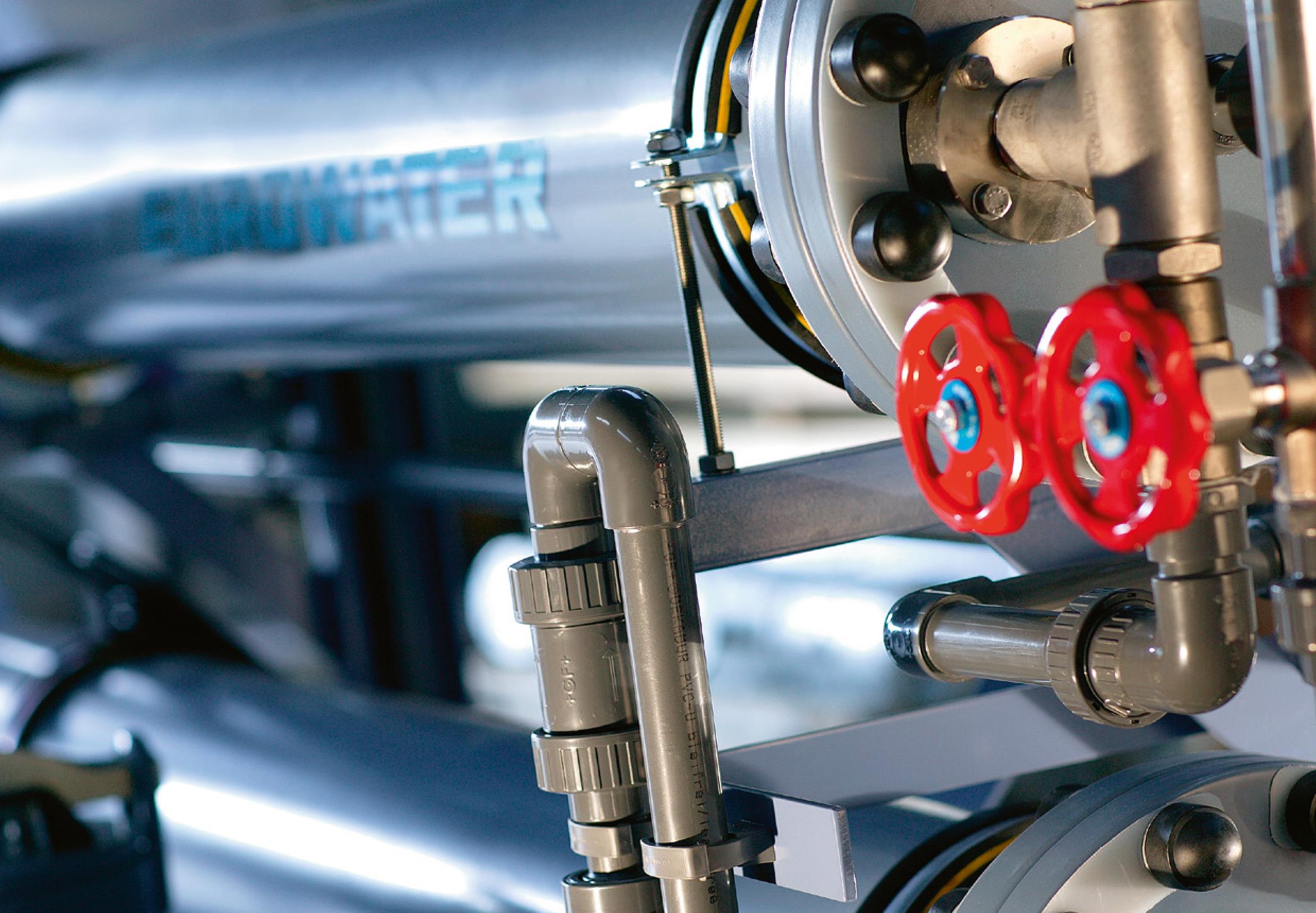

EUROWATER

Products "EUROWATER"

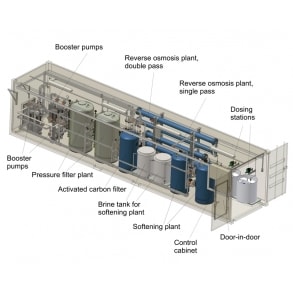

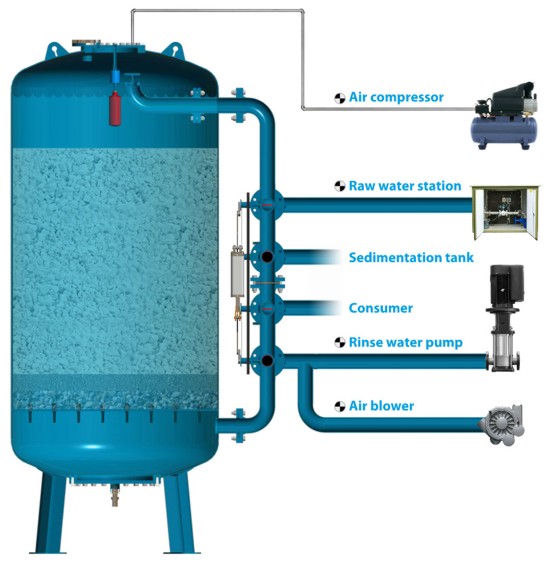

The water treatment company EUROWATER was founded in 1936 starting out with the production of filtration plants for filtration of water for dairy co-operatives. Since then, EUROWATER has developed into servicing customers within almost all industries.

Our activities are concentrated on development, production, and marketing of complete solutions for treatment of water. Our experience in this field includes

Numerous waterworks and private water supplies

Multifarious applications within all types of industrial companies and institutions

We are an independent group with 260 independent and experienced employees of which half is based in Denmark, mainly at our head office and production facilities.

The products are of very high quality. Solutions, choice of materials, and processes are constantly optimized in close co-operation with our supplying companies.

Our many years' experience and the packaged modular design guarantee a reliable plant, short delivery time, and competitive prices.

The production of larger pressure filters takes place at our subsidiary, Eurotank A/S, based near our head office in Denmark.

EUROWATER has subsidiary companies in 14 countries servicing our customers through 21 local offices. The relationship with our employees, customers, and collaborators is built on long-term relations. The international aspect forms the basis of a broad trade of experiences and places us among the leading manufacturers of water treatment plants in Europe.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production