BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

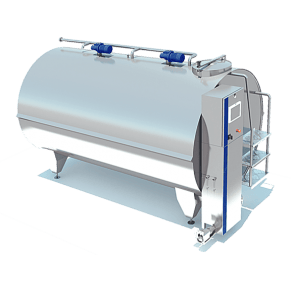

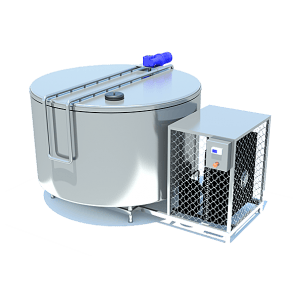

-milk & cheese >>

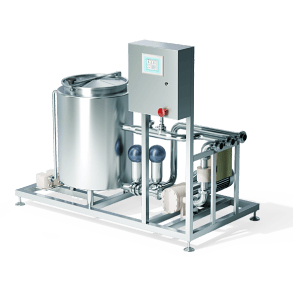

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

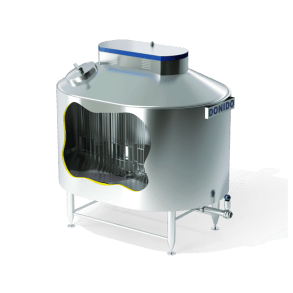

DONIDO

Products "DONIDO"

We transform the milk.

Our goal is to create a range of perfect dairy products for you to enjoy everyday and everywhere around the world.

We create new technologies to enrich your table.

High equipment quality and correct attitude to our customers are the company's standard.

We work for and with our customers to provide the best solutions.

The company was founded 1990 in Haskovo, Bulgaria with the idea to develop as a producer of equipment for the dairy industry.

The first equipment produced by DONIDO® is a pasteurizer for a dairy factory.

The first production line, created a year later was for production of the traditiona l for Bulgaria white cheese. Two years later the young company invested in two milk processing factories, where it experimented its new products, and developed new technologies. Through the years, with quick steps, DONIDO® is entering in all technological processes of the dairy industry, combining the best traditions of the old cheese makers with the newest technologies.

DONIDO® is the biggest producer of equipment and lines for the dairy industry in Bulgaria.

With its consecutive development policy and the proposed solutions we became a gold standard for the industry. The trademark DONIDO® is present in almost every Bulgarian dairy company.

There are 150 highly qualified specialists in the company, who are working in all the different fields of the whole technological process.

The design departments are supplied with contemporary 3D computer design systems (CAD/CAM) which allow them to take the correct decision in the beginning phase of the planning and to create the best option for the client.

DONIDO® guaranties final product corresponding to the highest technical and hygiene requirements, conformable to the individual vision and main characteristics of the region.

The production facility in Haskovo, Bulgaria is equipped with modern machinery and technologies that guarantee quality of the products.

The engineering structures perform precise and quick installation at every part of the World.

Highly qualified technologists complete the start up of the lines and consult the customer till the projected capacity of the line is achieved.

Customer service is our highest priority. Milk is a delicate raw material which requires care and devotion.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

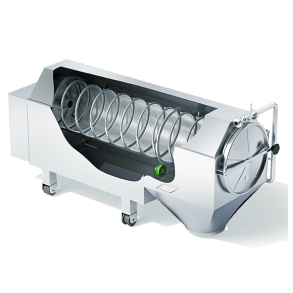

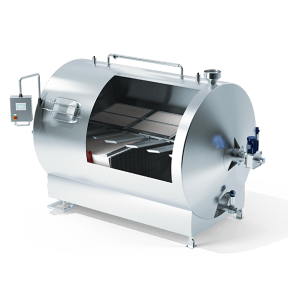

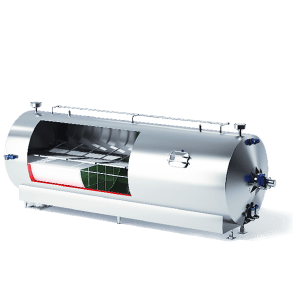

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production