BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

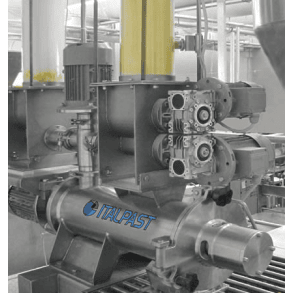

ITALPAST

Products "ITALPAST"

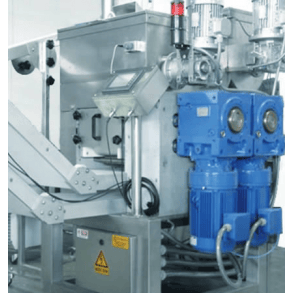

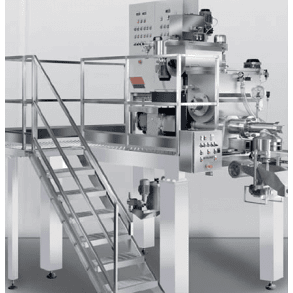

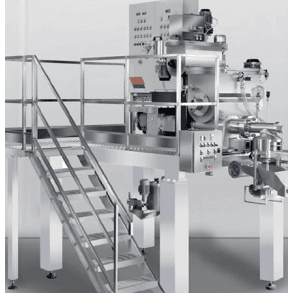

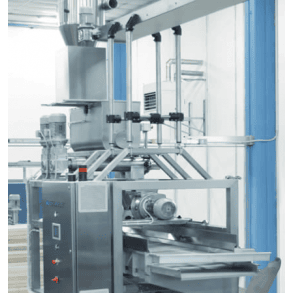

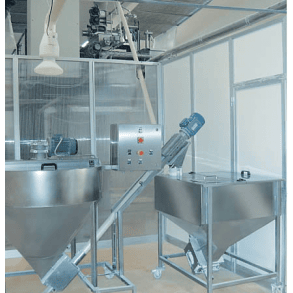

In the territory of Parma, headquarters of the European authority for the alimentary safety and core of the Italian Food Valley, our company engineers and manufactures machines and plants for the production of all types of alimentary pasta, from the more traditional type using durum wheat flour to the pasta produced with special flours, such as corn and rice flour.

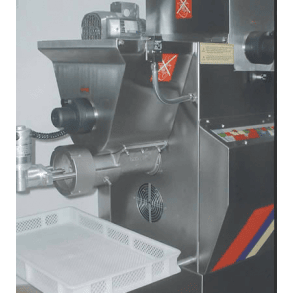

Be it dry pasta, fresh pasta, filled pasta, thermally-treated pasta or pre-cooked pasta for ready meals nowadays all the pasta world has a precious point of reference in Italpast.

Starting from the eighties Italpast have reached many targets thanks to the results of their research: increase in production outputs, reduction in servicing costs, higher returns on investments, full functional capacity of use, sanitization, automation in processing.

From the “simplest” pasta machine to the more complex production line we process your project and raise a layout on the basis of your specific requirements, fully exploiting our know-how while drawing up the most differentiated production plants.

Market evolution and differentiation have enabled Italpast to attain another point of excellence, i.e. the first-rate service for direct assistance: our customers are supported daily by our highly skilled technical staff.

As to research and development of products typology and production process Italpast have co-operated with different companies and research institutes to create various labs for production of special pasta, i.e. “functional” pasta (gluten-free, with high protein contents) with a view to reducing to the minimum the processing impact on the raw materials and exploit their organoleptic and nutritional properties at the same time.

- Go to: Full range of pasta processing equipment

- Go to: Fresh pasta pruduction machines

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production